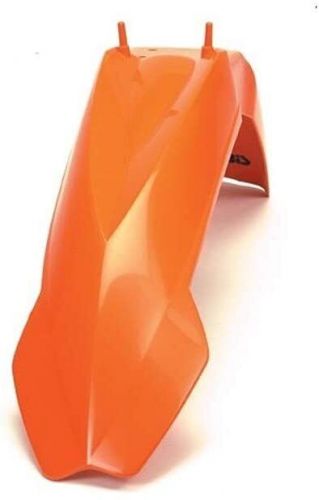

Acerbis 2040300237 Front Fender Orange Plastic For Ktm on 2040-parts.com

Flat Rock, North Carolina, United States

Fenders for Sale

Harley chopper bobbed rear fender bare metal used 545(US $90.00)

Harley chopper bobbed rear fender bare metal used 545(US $90.00) 1976-1979 kawasaki kz750b rear seat cover(US $75.00)

1976-1979 kawasaki kz750b rear seat cover(US $75.00) Harley-davidson springer front fender spacers big twin flathead knucklehead oem(US $20.00)

Harley-davidson springer front fender spacers big twin flathead knucklehead oem(US $20.00) 1977 kawasaki kz 750 b kz750b rear fender(US $45.00)

1977 kawasaki kz 750 b kz750b rear fender(US $45.00) For land rover discovery 5 2017-23 rear door wheel arch flare molding trim right(US $)

For land rover discovery 5 2017-23 rear door wheel arch flare molding trim right(US $) Suzuki gsxr 1000 k1 k2 k3 king carbon fibre rear hugger mudguard 01 02 03(US $)

Suzuki gsxr 1000 k1 k2 k3 king carbon fibre rear hugger mudguard 01 02 03(US $)

Enormous Jaguar sculpture graces Goodwood

Fri, 01 Jul 2011A 91-foot sculpture of the Jaguar E-type serves as a striking centerpiece for this year's Goodwood Festival of Speed in the United Kingdom. It took 10 days for a bridge-building company to install the 330,690-pound statue in front of the Goodwood House. That is the weight equivalent of 122 life-size copies of the Series 1 E-type.

2014 Citroen C1 revealed ahead of Geneva Motor Show

Mon, 24 Feb 2014Citroen has revealed pictures of its C1 city car ahead of its debut at the 2014 Geneva Motor Show – and it competes with the likes of the Renault Twingo, Peugeot 108 and Toyota Aygo for the crown of quirkiest small car of the show. Citroen 2014 Citroen C1 at Geneva: design Citroen says the new C1 features “more design”, which, although sounding a bit cringe-inducing, does signify how much the new car has changed over the outgoing model we first saw in 2005. Impressive efficiency figures are the result of “innovative technologies” says Citroen, as well as weight saving At 3.46m long, the 2014 Citroen C1 is 15cm longer than its predecessor.

Ford invents agile, low-cost solution for prototyping, customization and limited production [w/video]

Wed, 03 Jul 2013A new metal forming technique pioneered by Ford that drastically reduces the time and cost of producing low-volume and one-off body parts may lead to cost-effective customization, redesigns, one-offs and limited production runs. Ford Freeform Fabrication Technology (F3T) forms sheets of metal by two stylus-like tools, one on each side of the surface. Using CAD data they form the part to the exacting strength and finish tolerances usually associated with stamping dies.