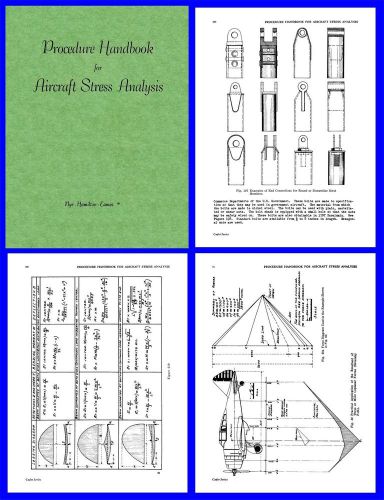

Procedure Handbook for Aircraft Stress Analysis.

Perfect scanned copy. 351 pages scanned as High resolution TIF images and then digitally cleaned page by page. This extremely detailed handbook written by Willis Nye, Dale Hamilton and James Eames details the Stress analysis of aircraft components and materials. Unlike my other manuals this a private publication (long past its copyright period). Packed with invaluable data including very detailed graphs and tabulated data. (See detailed Contents and Tables List below). Manual printed in 1940 by Aviation Press San Francisco, California. Also included on the CD is an PDF version of the handbook for easy browsing (Adobe Reader 7.0 supplied on the CD). Comes in a nicely printed Jewel case. See my other auctions for more vintage aircraft and engine manuals.

Contents

CHAPTER I - AIRCRAFT DESIGN SPECIFICATIONS

Influence of materials on the structure

Influence of payload on the type of structure

Performance requirements and their effect upon the type of structure

Type of materials which are employed in modern aircraft

Loads applied to the aircraft structure

Preliminary specifications.

CHAPTER II - MATERIALS OF AIRCRAFT CONSTRUCTION

Organic materials

Materials of wooden construction

Characteristics of airplane plywood

Bearing values of aircraft bolts in wooden members

Glues and gluing technique

Nails and woodscrews

Fabric

Plastics

Glass

Inorganic materials

Steel tubing

Steels

Heat treatment and quenching processes for steel

Stainless steel

Shot welding

Monelmetal

Aircraft bronzes

Aluminum and aluminum alloys

Heat treatment of aluminum alloys

Magnesium.

CHAPTER III - THE TESTING OF MATERIALS

Sources of material specification

Definitions pertaining to material testing

Definitions applying to the operations of heat treatment of steel

Testing sample dimensions

Impact testing machines

Hardness testing machines

Procedure involved in Brinell testing

Universal testing machines

Torsion testing machines

Fatigue testing machines

Fatigue of materials

Methods of hardness testing

Identification of aircraft tubing

Relation of Brinell test to material specification

Etching

Tensile tests

Elongation tests

Compression tests

Torsion testing

Bending tests

Fabrication tests

Resistance of material to shear

Chemical testing

Methods of testing wooden materials

Miscellaneous tests

Diagrammatic explanation of a standard testing machine for tension tests

Testing of glass

X-ray testing.

CHAPTER IV - PART ONE : A REVIEW OF APPLIED MECHANICS

1, Definitions of mechanics

2. Fundamental units

3. Classification of forces

4. Newton's Laws of motion

5. Methods of analysis

6. Vector and scalar quantities

7. Coplanar concurrent forces

8. Resultant of two coplanar concurrent forces

9. Bow's Notation

10. Resultant of three or more coplanar forces

11. Coplanar forces

12. Resultant of three or more coplanar parallel forces

13. Coplanar parallel forces: The couple

14. Coplanar forces not concurrent or parallel

15. Noncoplanar concurrent forces

16. Resultant of noncoplanar concurrent forces

17. Graphic method

18. Noncoplanar, nonconcurrent, nonparallel forces

19. Two and three force members: Redundant members;

20. Summary of Chapter Four Part One.

CHAPTER IV - PART TWO: A REVIEW OF APPLIED MECHANICS

21. Center of gravity and moment of inertia

22. Maximum and minimum moment of inertia

Method of locating the center of gravity of a fuselage

Determination of the center of gravity by graphical method

23. Motion

24. Rotation

25. Friction.

CHAPTER V - THE THEORY OF BEAM COMPONENTS

26. Stress and strain defined

27. Proportional limit and Hooke’s Law

28. Modulus of elasticity

Physical properties of materials

29. General types of beam

30. Types of beams employed in airplane construction;

31. Elements of beams

Vertical shear

Bending moment

32. External forces and internal forces

33. Neutral axis of a beam

34. Moment of inertia of an area

Formula of flexure and the modulus of rupture

35. Deflection of beams.

CHAPTER VI - COMPRESSION MEMBERS AND COLUMNS

36. Compression members and columns

37. Radius of gyration and the slenderness ratio

38. Column formulae

39. Design of column members;

40. Channels and stiffeners

41. Compressive strength of Dural columns of equal angle section

42. Torsion formulae

43. Torsion and bending;

44. Torsion bending and direct stress

45. Thin wall tubes and Aluminum compression struts

46. Torsion and buckling of open sections

47. Properties of strut sections

Determination of the neutral axis of symmetrical beam sections by graphical methods

Stainless steel column members.

CHAPTER VII - BEAM COLUMNS

48. Method of analysis

49. Precise equations

50. Approximate method for the determination of combined bending end axial load

51. Graphical solution of beam columns

52. Graphical solution of a simple beam;

53. Typical beam with a change in the distributed load

55. Shear.

CHAPTER VIII - THE GRAPHICAL ANALYSIS OF STRUCTURES

56. Introduction

57. Procedure involved in the graphical analysis of a structure

58. Solution of a typical truss by graphical methods

59. Solution of a typical drag truss problem by graphics

60. Solution of a typical fuselage problem by graphics

61. Phantom members

Graphical analysis of shell type fuselages.

CHAPTER IX - THE THEORY OF SHELL TYPE STRUCTURES

62. The thin plate as a structural element

63. Compressive strength of sheet and stiffener combinations

64. Wrinkling phenomena of thin walled cylinders

65. Flat sheets as structural elements

66. Functions of corrugations of thin sheets

67. Fittings and method of attachment for shell structures

68. Bulkhead rings

69. Lightening holes in flat sheets

70. Structural theory of shell fuselages

71. The Wagner beam

72. Internal forces on a thin walled cylinder

73. Corrugated column members

74. Design of metal spar members

75. Behaviour of shell fuselages undergoing torsional vibration.

CHAPTER X - THE THEORY OF JOINTS

76. Kinds of joints

77. Joints in wood

Wooden wing spars

Wooden wing ribs and the method of jointing

78. Splices in wooden members

79. Casein glue

80. Plywood joints

81. Aircraft welding

Typical welded joint design

Welded Joints

82. General theory concerning welded joint design

Gusset plates and welded joints

83. Electrical fused joints

84. Rivets and riveted connections

85. Types of riveted joints;

86. Investigation of the riveted joint

Shearing unit stress

Bearing unit stress

Tensile unit stress

Special types of rivets

Riveted joints in magnesium

Riveted joints in aluminum sheets

87. Practical design of rivets for a web

88. Design of strut end fittings

89. Aircraft bolts and pins

90. Analysis of a simple aileron horn

91. Analysis of a simple wing spar butt fitting

92. Aircraft structural fittings

93. Aircraft tie rode and wires.

APPENDIX

The design of bulkhead rings

General notes on the use of rolled structural shapes

Tables of technical functions and dimensions of structura1 shapes

Design of wood spars

Tubing and column design data

Conversion tables

Characteristics and formulae of various sections

Formulae for various beam loadings

Steel and duralumin column data

Properties of aircraft steel tubing, rounds, and streamlines

Column strength curves for chrome-molybdenum steel tubes.

LIST OF TABLES

Strength Coefficients of Different Kinds of Wood.

Properties of Spruce and Ash.

Tensile Strengths of Plywood Suitable for Aircraft Construction.

Properties of Airplane Spruce Conforming to A-N Specifications.

Allowable Bearing Strength of Steel Bolts in Wood.

Pyralin.

Organic Materials Used in Airplane Construction.

Division of Metals into Ferrous and Non-ferrous

Groups for Airplane Structures.

Number Designations for Airplane Steels.

Relationship of the Physical Properties of Aircraft Steels.

Chemical and Physical Properties of National Shelby Airplane Tubing

Modulus of Aircraft Materials.

Characteristics of Sheet Steel.

Modulus Versus Unit Stress for Stainless Steel Alloys.

Aluminum Alloys for Aircraft Construction.

Symbols of Aircraft Aluminum and Dural.

Mechanical Properties and Specifications for 17S Alloy Products.

Mechanical Properties and Specifications for 24S Alloy Products.

Uses of Aluminum Alloys.

Shearing Strength of Common Aluminum Alloys.

Mechanical Properties and Specifications for Aluminum Alloy Forgings.

17SO Aluminum Alloy Sheet.

Properties of Magnesium Alloys.

Typical Properties of Magnesium Rolled Sheet.

Brinell Hardness Numerals.

Hardness Conversion Table for Alloy Steels.

Chemical Composition of Steel Aircraft Tubing.

Physical Characteristics of Steel Aircraft Tubing

Chemical Composition of Aluminum Stock.

Load Elongation of Chrome Molybdenum Steel Tubing.

Column Formulae for Use in Airplane Design.

Values for Aluminum Column Formulae Constants.

Tip Sizes for Gas Welding Torches.

Lap Welds of Duralumin ( 17ST )

Strength of Spot Welds in Alclad 17ST

Safe Shearing Design Stresses for Aluminum Alloy Rivets.

Safe Design Value for One Rivet in Single Shear, Lb. per Sq. Inch.

Safe Bearing Design Stresses for Aluminum Alloys.

Safe Bearing Design Stresses for Various Driven Rivets.

Strength of Aluminum Alloy Bolts in Tension and Shear.

Bearing Strength of Bolts and Rivets in Aluminum Alloy Sheet.

Shearing Strength of Bolts, Pins and Rivets.

Rated Strength of Standard Tie Rods.

Strength of Round and Streamline Brace Wires.

Technical Functions and Dimensions of Structural Shapes.

Technical Functions and Dimensions of Structural Shapes ( Tees.)

Technical Function8 ani Dimensions of Structural Shapes (channels).

Technical Functions and Dimensions of Structural Shapes ( I Beams ).

Technical Functions and Dimensions of Structural Shapes (Angles).

Strength of Tapered Struts.

Size of Shackles and Clevis Pins for Cable Strength

Strength to Weight Factors of Aircraft Materials.

Torsional Modulus of rupture for Aluminum Alloy Round Tubing.

Column Data for Aluminum Alloys.

Column Data for Spruce.

Length of Tubing.

Strength of Elliptically Tapered Struts.

Torsional Modulus of Rupture for 1025 Round Steel Tubing.

Allowable Stresses in Pounds per Square Inch.

Allowable Stresses in Standard Corrugations.

Strength and Take-up of A-N Standard Turnbuckles.

Comparative Weight of Steel and Aluminum Sheet

Design Stresses f o Aluminum alloys.

Allowable Crushing Strength of Spruce (12% Moisture Content).

Properties of Hard Wire.

Safe Uniformly Distributed Load on 24" Corrugated Sheet Aluminum.

Comparison of Stainless Steel and Duralumin.

Allowable Column Stress for Solid Spruce Struts.

Allowable Column Stress for 1025 Round Steel Tubing .

Allowable Column and Crushing Stress for Chrome Molybdenum Round Tubing (75,000 psi,).

Physical Properties of Reinforced Plastics, Woods and Metals.

Millimeters Into Inches.

Inches Into Millimeters.

Fractions Into Decimals.

Conversion of Degrees to Radians.

Standard Seamless Round Steel Tubes for Airplane Structures.

Sample Computations for Column Curves.

Properties of Seamless Streamline Tubes.

** Note that the sample pages are a much lower resolution than those on the CD.

Please contact with further enquiries.

CD sent via First Class Airmail from Australia

Delivery within 10 working days of payment

Payment via PAYPAL to buyers outside Australia.

Australian buyers: payment by most methods

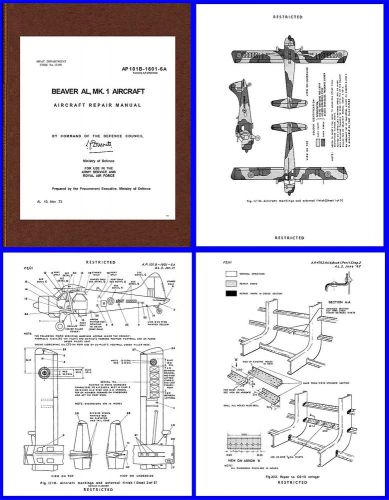

Beaver al mk1 aircraft repair manual

Beaver al mk1 aircraft repair manual 1975 cessna 150 owner's manual 150m d1033-13 printed 9/74

1975 cessna 150 owner's manual 150m d1033-13 printed 9/74 (g-ii, g-iii, g-iv) gulfstream aircraft familiarization manual volumes i & ii(US $36.99)

(g-ii, g-iii, g-iv) gulfstream aircraft familiarization manual volumes i & ii(US $36.99) Gulfstream g-iv maintenance schematic manual (flightsafety international)(US $160.00)

Gulfstream g-iv maintenance schematic manual (flightsafety international)(US $160.00) Cae cessna citation x pilot training manual(US $162.50)

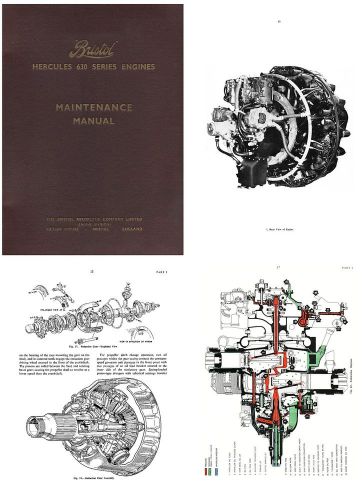

Cae cessna citation x pilot training manual(US $162.50) Bristol hercules aero engine maintenance manual on cd

Bristol hercules aero engine maintenance manual on cd