Arp Headstuds Duramax Headstud Kit 01-07 Gm Lb7/lly/lbz #230-4201 on 2040-parts.com

Winchester, Kentucky, US

| ||||||||

|

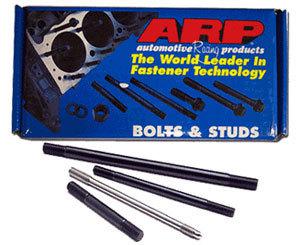

ARP is the undisputed world leader in automotive fasteners. They manufacture every fastener, bolt and nut that the world's top engine and chassis builders rely on in house. ARP engineers ensure that every piece will outperform any other fastener on the market today. That's why so many top engine builders rely on ARP racing products to hold their engines together. To overcome head gasket failures that can occur in diesel engines employed in truck and RV applications, industry leader ARP has introduced extra heavy-duty head studs for the popular Ford, Dodge and GM power plants. These ARP studs are rated at 220,000 psi tensile strength, and provide the clamping force required to keep cylinder heads from lifting due to higher combustion pressures. The studs are manufactured in ARP's Santa Paula, CA plant from proprietary ARP 2000 material, with threads rolled after heat-treat to provide optimum fatigue strength. They are centerless ground to assure perfect concentricity. The ends of the studs are broached to facilitate easy installation. This feature also enables the cylinder head to be removed in tight quarters. Also included in each kit are heat-treated, chrome-moly steel 12-point nuts and parallel-ground washers. They are black oxide finished for extra durability.You should know that ARP® uses a premium grade 8740 alloy that is rated far superior to "aircraft" quality. Then, each stud is precisely heat-treated to 200,000 psi. Following heat treat, each stud is centerless ground to make it as close to perfectly concentric as possible. This procedure involves about ten very slight cuts and results in an exceptionally straight part. It's important to note that lesser quality studs are not even centerless ground, the material is thread rolled in bar stock form (mostly before heat-treat, when the material is easier to machine). Because ARP® studs are manufactured to such exacting tolerances, you will note that gaskets and cylinder heads literally glide into position and are perfectly aligned, something that won't happen with inferior quality head studs. ARP® studs are thread rolled after heat-treat, which gives them about 1000% (that's ten times) better fatigue strength than those studs that are threaded prior to heat-treat. You will also note that ARP® offers specially undercut studs for several engines. This procedure (done only to the shorter studs) more equalizes the "stretch" of both studs, which makes for a more consistent clamping force, one that compensates for head gasket compression when the head is installed. This helps prevent blown head gaskets, and assures optimum sealing!

| ||||||||

|

| |

| |

|

| |

|

Cylinder Heads & Parts for Sale

96-00 honda civic 97-01 honda cr-v crv power mirror switch control button grey(US $9.99)

96-00 honda civic 97-01 honda cr-v crv power mirror switch control button grey(US $9.99) 97 98 99 00 01 02 03 pontiac chevy buick olds 3.8l v6 cylinder head(US $34.95)

97 98 99 00 01 02 03 pontiac chevy buick olds 3.8l v6 cylinder head(US $34.95) 97 98 99 00 01 02 03 pontiac chevy buick olds 3.8l v6 cylinder head(US $34.96)

97 98 99 00 01 02 03 pontiac chevy buick olds 3.8l v6 cylinder head(US $34.96) 82 volvo diesel head 240 264 265 80 81 83 84 85 86 6 cylinder cyl dl gl audi vw(US $224.99)

82 volvo diesel head 240 264 265 80 81 83 84 85 86 6 cylinder cyl dl gl audi vw(US $224.99) Bmw vanos unit e36 e34 e39 m50 s50 m52 s52 323 325 328 525 528 m3(US $75.00)

Bmw vanos unit e36 e34 e39 m50 s50 m52 s52 323 325 328 525 528 m3(US $75.00) Bmw e36 e34 e39 rebuilt vanos unit m50 m52 s50 s52 325 328 525 528 m3 1993-1999(US $199.00)

Bmw e36 e34 e39 rebuilt vanos unit m50 m52 s50 s52 325 328 525 528 m3 1993-1999(US $199.00)

New Mustang Madness at Venice Beach

Fri, 06 Dec 2013Rick the Hippie rode by us on a battleship-grey 1939 Schwinn--thin, wispy long hair waggling in the chilly breeze, wearing board shorts and a grey flannel Hurley jacket over four layers that puffed out and made him resemble a mushroom. We were having a conversation about the Shelby GT. His eyes, wrapped behind layers of tan wrinkles, lit up.

2014 Chevrolet Camaro Z/28 drive review

Mon, 24 Mar 2014What is it? The 2014 Camaro Z/28 is the most track-capable Chevrolet Camaro to date from the factory. Everything done to the car is in an effort to shave lap times.

Concept Car of the Week: Dodge M4S PPG Turbo Interceptor (1985)

Fri, 03 Jan 2014As a major paint supplier of Detroit's big three, PPG would commission every year a car to be used as a pace car in the Indy Car World Series. In 1984 Chrysler began the development of a mid-engined, rear-wheel drive car using an experimental powertrain. To avoid the costs of creating a whole new chassis, the M4S is based on a modified Huffaker tubular chassis with full roll cage taken from the Pontiac Fiero IMSA race car, only lengthened to a 100-inch wheelbase.