Audi outlines seven tech innovations

Thu, 01 Mar 2012Audi has revealed details of seven new innovations being explored by its designers and engineers including electromobility, ultra-lightweight construction, networked mobility and lighting technology.

Lighting design

The team in charge of lighting design – an area in which the company is the current leader in terms of LED daytime running lights and headlights – and next up they plan on introducing OLED technology (Organic Light Emitting Diode) to its vehicle range. Only a few nanometers thick, this paste-like material spans the space between the anode and cathode, both of which are enveloped in an electrically conductive coating.

The result is a lighting solution that can be applies to the car like a vinyl graphic – spilling out from the traditional boundaries of the lamp cluster.

Autonomous parking

Audi is also developing a fully autonomous parking system whereby the driver would be able to leave the car and then, using a mobile phone, be able to instruct the car to maneuver into a bay using a combination of sensors and a route map provided by the garage's central computer.

HMI

Audi will introduce a revised version of its Audi Touchpad – originally fitted to the A8 – integrated into the MMI knob of the 2013 A3, as we reported from CES. However the next generation will feature multitouch, similar to that found on smartphones and tablets that incorporates haptic feedback and pinch to zoom alongside the existing handwriting recognition ability. This will be partnered with new head-up displays, voice controls and gestures, which are aimed at reducing driver distraction while increasing control.

Predictive suspension

Audi plans on using a similar system to Mercedes-Benz's that will change damper rates by using cameras that scan the 20 meters of road ahead of the car. A stereo camera, mounted ahead of the rearview mirror, will be joined by Photo-Mixed Detectors (PMD) that rely on both radar and laser systems.

Wireless charging

Dubbed Audi Wireless Charging, the tech was developed alongside the WiTricity Corporation, with the American company supplying the coil systems that are integrated into the floor plates, while the secondary coil is placed on the underside of the vehicle.

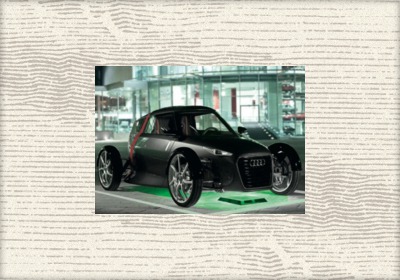

Lightweight construction

Audi has traditionally used aluminum to reduce the vehicle weight by as much as 40 percent compared to a standard steel chassis. But with ever more pressure to improve efficiency, it is planning to use a mixture of aluminum, steel and carbon fiber reinforced plastic (CFRP) components to reduce weight as well as increasing strength. This includes a fiberglass reinforced plastic (FRP) suspension spring, which is around 40 percent lighter as well as stronger.

By Rufus Thompson