One of the reason why Mercedes are so smooth and quiet is that their vehicles has anti humming rotors (harmonic balancing) rotors from the factory. 99% of the companies that sell cross drilled rotors does not offer harmonic balancing technology it will create unwanted noise inside the cabin during braking.

DRT harmonic balancing design will help reduce the humming noise during braking. Conventional (old school) cross drilled or slotted rotor create harmonic frequencies (humming noise) during braking. Harmonic balancing drilled/slotted rotors are none directional. When the brake pedal is applied, one side will create positive harmonic frequencies, and the opposite side will create negative harmonic frequencies. The positive and negative frequencies will counter balance each other to reduce humming noise. DRT harmonic balancing rotors will eliminate humming noise in the cabin for a comfortable driving experience.

Harmonic balancing rotors does not have any negative affect on the performance nor will it reduce the longevity of the rotor.

Please ask question if you're not sure

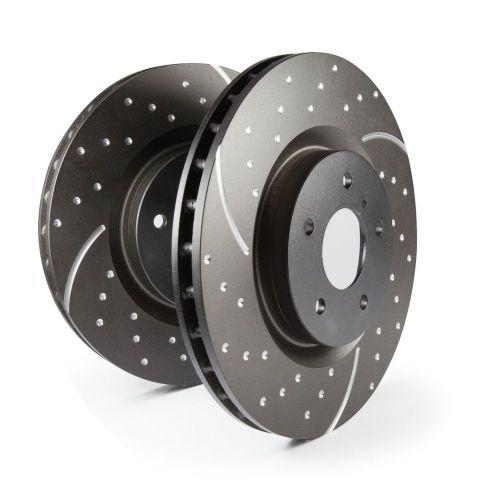

photos are for illustration only patterns are the same but size will vary depending on model

Reduce operating temperature

Prevent warping

Prevent fading

Fast degassing

Reduce humming noise

Increase pad grip

Reduced stopping distance

3/16 holes stronger vs. 1/4 holes

Chamfered holes

Same vane count as OEM

Hour glass shape vane 50/50 heat dissipation

Tapered slots help channel out brake dust

Shed off water under wet-condition

Gray Z coating helps slow rust

Compatible with stock calipers, pads, wheels

Zimmermann Z Coated

No formation of rust at the hub and herewith improved visual appearance. Immidiate functional capability without removal of the coating before mounting.

Zimmermann Quality

Zimmermann brake discs are made to the same standard as your OEM parts. Every Zimmermann rotor contain copper, molybdenum, titanium and carbon which help increase friction, resist cracking during high performance repeat stop situation, resistant to oxidation, reduce brake pad squeal. Each individual brake disc of Zimmermann matches exactly with the OEM parts.

Over the last few years, an increasing number of brake discs which are not identical to OEM part in terms of their design and function have been sold on the market. Tests have revealed that basic material specifications in particular, but also changes to tolerances result in deformations and increased cracking of brake discs.

Otto Zimmermann GmbH has been performing inertia dynamometer tests and driving tests together with TÜV NORD Mobilität GmbH & Co. KG on an ongoing basis for more than 10 years, at great financial cost.

Dynamometer inertia load testing

Zimmermann after 200 inertia load test

Zimmermann brake discs are "spare parts of the same quality" as original brake discs. The third-country brake discs tested by TÜV NORD do not meet this claim.

Competitors zinc plated version after 81 inertia load test

In all the brake discs tested, third-country products break considerably more quickly. The Zimmermann brake disc and the original product therefore have a significantly longer life expectancy.

The thermo-mechanical deformation is identical for the Zimmermann brake disc and the original brake disc. The third-country brake disc falls significantly below this level with respect to nearly all the criteria tested.

- Made in Germany in conformity with DIN EN ISO 9001:2008 and

DIN ISO TS 16949

- Consistently high product quality meeting the very highest quality standards

- Responsible awarness of your safety

- Reliability in-house development

- Permanent program maintenance and extension

Would you install Chinese rotors in your German cars?

Some of our competitor's rotors

Don't be fooled by the low quality zinc plated rotors that will cost you more for the long run. These rotors has very low quality the metallurgy it does not meet the manufacturer's specification of your vehicle. Most sellers will fool you with a very high price than marked it down by 50% off leading you to beleive it's a great deal. Seller will not disclose information about the blank rotor. If it's too good to be true it's usually is.

-

Tapered vane struction vane does not meet OEM spec. uneven heat dissipation

-

Low quality metallurgy that does not meet OEM spec.

-

Zinc plating are not intended for brake rotor

-

Hyrochloric acid from brake dust and road elements will deteriorate zinc very quickly

-

Zinc plating a very low quality rotor will not improve the quality of the rotor

-

These rotor will cost you more money and down time

Choose your pattern, failure to choose will delay shipping

Cross Drilled/Slotted:

Recommended for aggressive driver who want cooling of the cross drilled with an extra bite. The slot will increase initial pad bite when brake pedal is applied. The slots also help keep the pads surfaces clean and free of glazing as well as heat dissipation.

Slotted:

Ebc brakes dp2836 ebc greenstuff 2000 series sport brake pads(US $87.01)

Ebc brakes dp2836 ebc greenstuff 2000 series sport brake pads(US $87.01) Ebc brakes gd7223 rotor fits 02-15 avalon camry es300 is250 sienna solara(US $204.83)

Ebc brakes gd7223 rotor fits 02-15 avalon camry es300 is250 sienna solara(US $204.83) Ebc brakes gd7240 rotor fits 05-15 300 challenger charger magnum(US $237.02)

Ebc brakes gd7240 rotor fits 05-15 300 challenger charger magnum(US $237.02) Ebc brakes ud784 ebc ultimax brake pads(US $64.67)

Ebc brakes ud784 ebc ultimax brake pads(US $64.67) Ebc brakes ud273 ebc ultimax brake pads fits accord civic civic del sol crx(US $45.12)

Ebc brakes ud273 ebc ultimax brake pads fits accord civic civic del sol crx(US $45.12) Ebc brakes dp21329 ebc greenstuff 2000 series sport brake pads(US $96.88)

Ebc brakes dp21329 ebc greenstuff 2000 series sport brake pads(US $96.88)