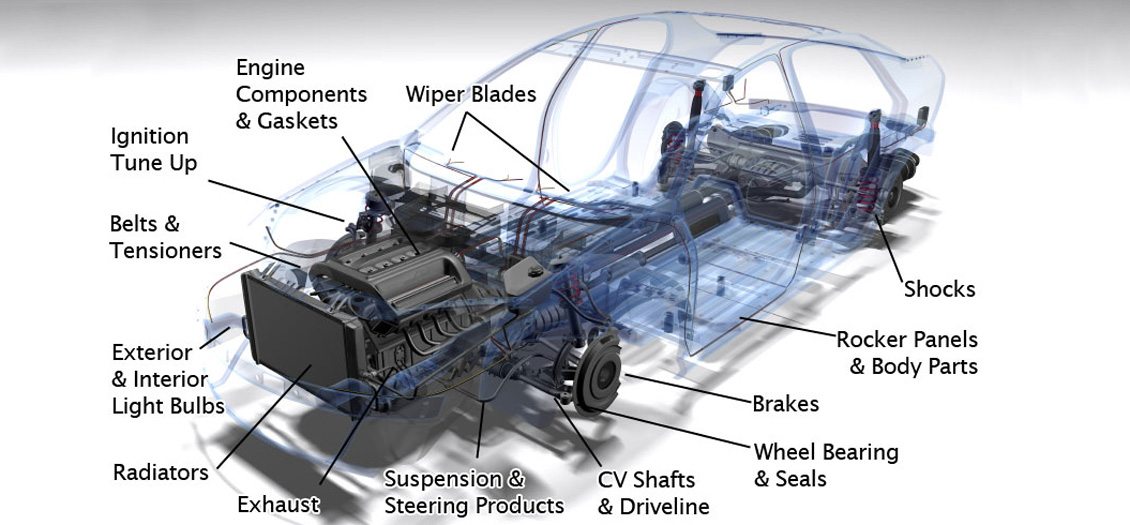

Starter Motor To Nissan Forklift Lift Trucks F3 F03 w/ TD42 Diesel Engine 1989-On

Description:

The starter is an electrical motor that uses power from the vehicle's battery in order to start the engine.

Replace for OEM num:

| NISSAN |

| 23300-34T00 |

| 23300-06J01 |

| 23300-06J02 |

| 23300-06J04 |

| LESTER |

| 18058 |

Features:

*Direct Replacement for your Starter Motor.

*Quality: ROHS; ISO/TS16949; ISO9001:2008

*Fitment Tested

*Top quality Aftermarket part.

24V, 2.5KW, 11T , CW.

Suit:

Nissan F03 Series Lift Trucks w/ TD42 Diesel Engine 1989-ON

Specifications:

| Voltage |

KW |

Teeth |

Rotation |

Mount Hole Diameter |

Flange Diameter |

Pinion At Rest |

Pinion Diameter |

Overall Length |

Mount Holes Cnt to Cnt |

| 24V |

2.5kW |

11TH |

CW |

3 x 13 |

105 |

12 |

40 |

240 |

80 x 114 x 139 |

Package:

1* Starter Motor

Item number:

SMOTOR-NS000

*Tips: Symptoms of Wear or Failure

Engine may not crank over when attempting to start the vehicle

Abnormal noise when starter is engaged

*Tips: Related Repair Advice

Many vehicles have a special ignition key that is electronically coded to start your vehicle. If the key or the system is having problems, the symptom may be the same as a faulty starter.

A weak or dead battery can exhibit the same symptoms as a faulty starter. The battery should be inspected and replaced as necessary before replacing the starter.

Corroded and/or loose battery terminals can exhibit the same symptoms as a faulty starter. They will need to be cleaned and possibly replaced before a failed starter can be properly diagnosed.

A faulty ignition switch may have the same symptoms as a defective starter

For vehicles with an automatic transmission, the neutral safety switch should be inspected. Manual transmission vehicles should have the clutch pedal switch checked.

*Tips: How To Replace Starter Motor

Changing a starter can be a difficult, time consuming job. If you're confident that you're able to change the starter yourself, read on! You should check several other parts before you decide it's time to change the car starter.

- Check the condition of the battery. A weak battery can't turn the starter over. Make sure the battery is at full strength before you blame the starter. Your car's instrument cluster should indicate when there is a low battery with either a warning light or ammeter.

- Also check the battery connections, the wires going to the starter, and the starter connection. The most important wire is the big one running down the back of the battery. It is the wire that goes from the battery to the starter. All connections should be snug. Check that the insulation on the wires is intact. Tighten any connections loose enough to wiggle by hand.

- Check the starter solenoid. The starter solenoid is a special switch that turns the starter on and off. Solenoids rarely cost more than $10, and they are fairly easy to replace. When you turn the key, have a friend listen to the solenoid for a clicking sound. If there's no sound, assume the solenoid is broken and needs to be replaced.

- If the automotive engine is turning over and still won't start, it might be due to another problem unrelated to the starter or battery. Anything from a dirty air filter, worn spark plugs, bad spark plug wires, a worn distributor cap, insufficient fuel reaching the engine or even blown gaskets can prevent a car from starting. If you can't isolate the problem through trial and error, it may be time to take the car to a mechanic for check-up or repair.

Once you've determined that the problem is not resolved by troubleshooting the above issues, it may very well be that you need to replace the starter.

- 1.Disconnect the battery cables in order to reduce the possibility of accidentally shocking yourself.

- 2.Remove the electrical connections from the side of the starter. There are usually two wires: a positive and a negative wire. Remove the positive wire first, and then remove the negative wire from the starter. You may want to mark the connections with a paint pen to help you correctly reconnect the connectors to their proper terminals. To remove the connections, you'll need to use an open face wrench or socket wrench to remove the bolts.

After both of the electrical connections are removed, you'll need to unbolt the starter from the chassis. Before you remove these bolts, take note of how the starter is oriented. You may want to mark the bolts with paint pens. There are usually only two or three bolts that attach the starter to the vehicle.

- 3.Remove the starter. In preparation, look closely at your car and determine what path will be easiest for removing the starter. It might be a tight fit, but you'll need to twist and pull the starter around various engine and frame parts in order to get it out of the car. Some cars may be particularly tight, especially those with front wheel drive. You may have to remove other parts in order to get enough space the pull the starter out. If you do remove engine parts, take care to remember their proper location. Replace bolts into the same place they came from once you pull a piece off. This will help you keep up with all of the pieces.

- 4.Once you've pulled the starter out, you can put the new starter in its place. You'll need to put it back in the exact same way you pulled the old starter out. Once you have it in place, put in a bolt just enough to hold the starter in place. Then connect the electrical connections beginning with the ground wire. Once the ground wire is connected, attach the rest of the wiring. Next, install the rest of the bolts holding the starter to the frame. Check to see that all bolts are tight.

Quick Tips:

- Do not overtighten the bolts holding the starter to the frame. Check the instructions that come with your starter to determine the appropriate torque.