UPGRADE TO 4.250 STROKE FOR $500 ADDITIONAL.

IMPORTANT: CAMSHAFT SHOWN IN EBAY PHOTOS IS NOT INCLUDED AT THE BUY

IT NOW PRICE. EBAY PHOTOS ARE FOR ILLUSTRATIVE PURPOSES ONLY! BILLET

OIL PAN RAIL SHOWN IN EBAY PHOTO IS NOT INCLUDED AT THE BUY IT NOW

PRICE. FREE SHIPPING IS ONLY TO BUSINESS ADDRESS, LIFT GATE AND/OR

RESIDENTIAL IS $195 ADDITIONAL.

Contact Jerry with questions or message through Ebay.

Please see our website and take our shop tour to see the kind of work we do. Thank you and look forward to hearing from you.

Jerry Long, Div Mngr

SAG Performance Group

Phone:

Fax: (877) 309-1271

Website: https:/www.sagperfomance

SEE BELOW FOR A WEALTH OF INFORMATION ON THE NEW DART NEXT BLOCK:

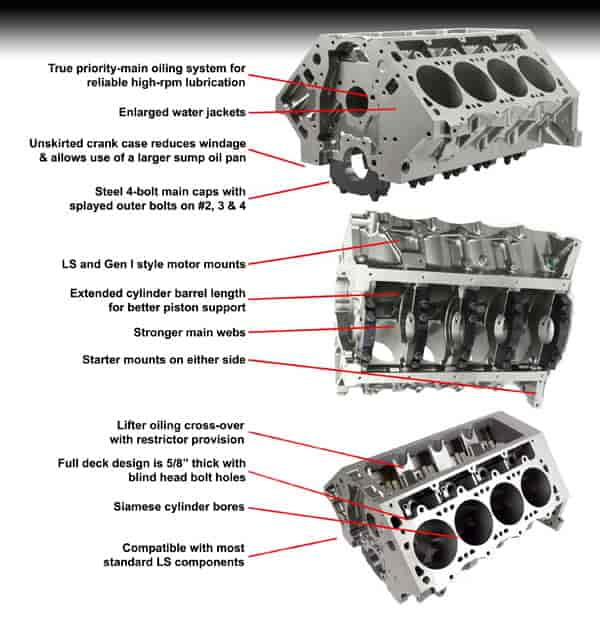

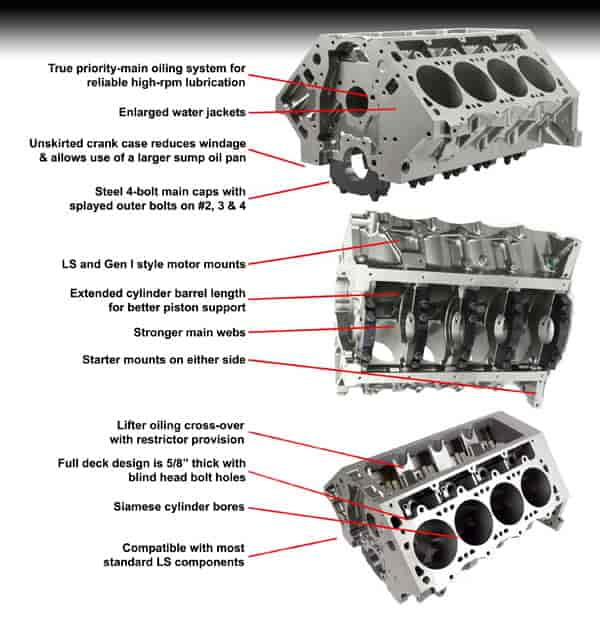

Features:

| Reduced windage and increased power

Extended cylinder barrel length

Siamese cylinder bores

Special RMR Iron Alloy

4.000'' or 4.125'' w/ 4.200'' Maximum Bore

4.200'' x 4.100'' Maximum Bore & Stroke

454 Cubic Inch Maximum

Stock LS Camshaft Position

Accepts Standard Camshaft Belt Drive or Chain Drive (Cloyes p/n 9-3658TX3)

1.565'' O.D. Camshaft Snout

.275'' Cylinder Wall Thickness @ 4.185'' Bore

9.240'' Deck Height w / extended cylinder barrels .375'' at bottom

5/8'' (.625'') Deck Thickness

1.500'' Diameter Freeze Plugs

Cam retaining plate: Dart cam retaining plate / Cover. Dart 301-32226000

Billet Steel 4-Bolt Splayed Main Caps w/Center Thrust

.8427'' - .8437'' Lifter Bores (up to .937'' keyed w/ 1.062'' dia. bushing)

Low Volume Priority Main Oiling System w/Center Crossover

Melling or Stock LS Oil Pump

Must Use Remote Oil Filter

Special Oil Pan Required: Moroso, Canton and Stef's

Stock LS style Rear Main Seal with Factory Cover

Factory LS Starter w/Driver and Passenger Mounting Options

Main Bolts: Inners - 7/16'' x 3.600''; Outer - 7/16'' x 2.900''

Studs Holes: Head 10-bolt Pattern with 7/16'', 3/8'', and 8mm sizes

Stud Length in Block: 1.000'' Thread Depth

Factory LS Timing Cover and Front Seal

227 lbs w/Main Caps

100% Made in the USA! |

The New Dart LS Next Engine Blocks are designed to

eliminate the high RPM power loss and the problem of separate bays in

the crankcase associated with the ''Y-Block'' design of the LS engine

series. This has been accomplished by using the conventional style small

and big block Chevy 4-bolt steel main caps with 7/16" bolts, full main

webbing and crank barrel around a standard LS rotating assembly for

maximum bottom end strength!

The cylinder barrels are extended by .375" at the bottom, providing the

effective equivalent of a 9.615" deck height in terms of potential

supported piston travel, while maintaining a standard 9.240" actual deck

height for maximum compatibility with available components. This

equates to greater piston support with long stroke combinations and

allows for better piston designs to increase stability. While extra

thick Siamese cylinder bores allow for large displacement capacity!

The oiling system has also been revised the stock internal main oil

galley has been eliminated and a revised low restriction priority main

oiling system is utilized. A pro-stock / pro-mod big block style stepped

main oil galley measuring 9/16"-1/2"-7/16" is employed and increases

volume but most importantly there is no loss of pressure or velocity at

the front of the block!

At the top end of the block a 5/8" thick full deck design with six head

bolts per cylinder is utilized to provide secure clamping strength and

versatility for power adder applications. LSX style lifter bosses and

guides are utilized while the provisions for oil restrictors in the

lifter valley simplify the installation and removal of restrictors!

Dart’s LS Next Block Performs Well In Oil-system Tests

Dart’s new LS Next iron cylinder block is one step closer to hitting

the market following a series of oil-system tests. The block was first

shown at the SEMA show last November, and it’s designed to take

advantage of the LS engine’s positive attributes while removing the

negatives from the equation. Basically, the new block supports LS

cylinder heads and other major components but replaces the troublesome

Y-block side skirts with Gen I-style main caps and oil-pan rails. The

result is less crank windage and stronger main web.

The

oiling system was the most critical issue that company founder Richard

Maskin and his team tackled during the block’s development. The first

test used an external pump and a modified Moroso Rocket-block pan core.

The second test utilized a stock LS oil pump, which was modified with a

weaker pressure spring, and a Moroso LS oil pan with pan rail spacers to

make up the difference in the skirt length. These adjustments

maintained the oil desired oil pressure in the engine without the

excessive volume that the LS often requires.

The

oiling system was the most critical issue that company founder Richard

Maskin and his team tackled during the block’s development. The first

test used an external pump and a modified Moroso Rocket-block pan core.

The second test utilized a stock LS oil pump, which was modified with a

weaker pressure spring, and a Moroso LS oil pan with pan rail spacers to

make up the difference in the skirt length. These adjustments

maintained the oil desired oil pressure in the engine without the

excessive volume that the LS often requires.

“According to my sources, the stock LS7 uses somewhere around 18

gallons per minute revved up, while our design uses much less and still

provides more-than-adequate oiling across the board,” explains Maskin.

“So far, we’ve created two blocks – the first one was cut up for

inspection, and the block used for this test was number two. Now that

the initial testing has been run, we plan to pour 25 production blocks

next week, which will be available for purchase on or about the first of

May.

“We’ve got two more tests to run,” continues Maskin. “The first being

a Pro Stock dry-sump system with 25 inches or more of vacuum to see

what power potential is really in the oiling system. For the second

test, we’ll be going back to the stock pump with an all-out, baffled,

screened, wet-sump oil pan.”

More power than expected

The test engine was fitted with Dart’s CNC-machined LS1 heads, a “reasonably small” solid-roller cam, GM intake and 850cfm carb.

“As far as performance goes, there are plenty of performance parts

out there – heads, manifolds, etc. that are much better than what we

used in this engine,” says Maskin. “We were just trying to prove that

the block worked as it was designed to work.”

Experts at Lingenfelter Performance and Nickens Racing Engines had

earlier suggested to Maskin that the engine with those parts would make

about 640 to 660 horsepower. As indicated by the dyno results below, the

engine hit a peak of 740 horsepower and averaged 701 horsepower from

5,600 to 8,000 rpm.

Dart’s

new LS Next block features 4-bolt steel main caps with 7/16-inch bolts

and full main webbing for maximum bottom-end strength. The cylinder

barrels are .375-inch longer for better piston support and ring seal. It

comes with a 9.240-inch deck height and 5/8-inch deck thickness. The

siamesed cylinder bores can be opened up to 4.200 inches, allowing for

large-displacement options.

Dart’s

new LS Next block features 4-bolt steel main caps with 7/16-inch bolts

and full main webbing for maximum bottom-end strength. The cylinder

barrels are .375-inch longer for better piston support and ring seal. It

comes with a 9.240-inch deck height and 5/8-inch deck thickness. The

siamesed cylinder bores can be opened up to 4.200 inches, allowing for

large-displacement options.

The block also features blind head bolts: four 7/16-inch head bolts,

one 3/8-inch and one stock-sized inner hole per cylinder to improve

clamp force in power-adder applications. There are provisions for oil

restrictors in the lifter valley to complement the low-volume, priority

main oiling system. LSX-style lifter bosses and dog-bone provisions are

also included with the LS Next block – it will easily accommodate

1.060-inch bushings with .937-inch lifters. The block also features a

Pro Stock/Pro Mod-type big-block style stepped main oil galley. Lastly,

the water jacket around the No. 1 cylinder has been expanded as well as

around the outside of each cylinder barrel for additional cooling

capacity.

Test Engine Specs:

Test Engine Specs:

- Bore: 4.155 inch

- Stroke: 4.00 inch

- Rod Length: 6.125 inch

- Compression Ratio: 12.5:1

- Pistons: Mahle flat top

- Engine Bearings: Clevite

- Camshaft: Mechanical roller 255/265 duration, .670-inch lift

- Rocker: Harland Sharp Roller

- Heads: Dart w/ 2.08-inch I/1.60-inch E

- Intake: Chevy Performance single plane

- Carburetor: Demon 850cfm

- Ignition: HEI, with 30 degrees timing

- Oil Pump: Moroso external, Melling stock replacement

- Oil Pan: Moroso

- Headers: Hedman

Check out this interview with Richard Maskin from the 2012 PRI show as he discusses the LS Next block.

https://www.enginelabs.com/news/darts-ls-next-block-performs-well-in-oil-system-tests/