Rustproof Brake line kit for 2003-07 Silverado Sierra 1500 see important details

-PVF lines are better than stainless steel as they are resistant

to rust and abrasion, and yet seal better when assembled.

and they do not suffer metal fatigue as they flex better with the car body.

Many professionals prefer -PVF lines in their restorations!

Buy for the future brake job!!!

replace your rusted lines!!

Polyvinylfluoride (PVF) is a durable, abrasion resistant outer coating for brake lines. - PVF exceeds 2,000 hours of salt spray testing, and is highly resistant to abrasion. - The PVF topcoat -is applied -and factory cured over an electro plated zinc -surface. - First used in Europe, this coating is now widely used on new cars and -trucks all over the world. - It is better than stainless steel because the inverted -flare connections on our lines still contain copper to seal the fittings. - Retrofitting stainless steel on inverted -flare fittings results in leaks because the -copper sealant -is not present.

Important! Please enter your truck info in the compatibility section in this listing.

If not sure if it fits your truck please message us for assistance.

This kit fits:

2003-07 Silverado Sierra 1500 see important details

Information on lines are for OEM brake systems only. The lines may not fit any brake system that has been modified.

2003-07 Silverado Sierra 1500 see important details

Information on lines are for OEM brake systems only. The lines may not fit any brake system that has been modified.

2003-07 Silverado Sierra 1500 see important details

Information on lines are for OEM brake systems only. The lines may not fit any brake system that has been modified.

2003-07 Silverado Sierra 1500 see important details

Information on lines are for OEM brake systems only. The lines may not fit any brake system that has been modified.

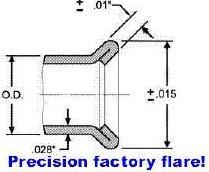

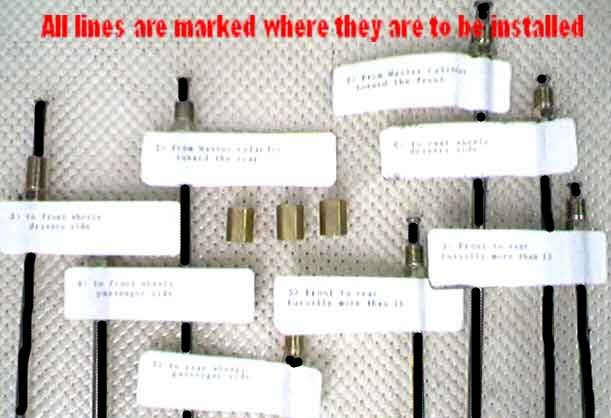

This is a complete brake line replacement kit. All lines are supplied double-flared at each end with S.A.E. specified male inverted flare fittings attached -- ready for quick easy installation. All brake lines have an extra long nut on one end to seat in late model deep-seated wheel cylinders. These -malleable lines are easy to bend or coil without collapsing the tubing or restricting the flow of brake fluid. A chart of your brake system is included and all lines are clearly marked and numbered as to where they should be installed. Couplers are included where necessary.

-

Powered by SixBit's eCommerce Solution