|

Continental Aircraft Engine, Models C75, C85, C90 & O-200 Overhaul Manual

Perfect Scanned copy.118 pages scanned as High resolution TIF images and then digitally cleaned page by page. Packed with invaluable data including many Photographs, diagrams and Tables (See List below). These engines were used in a huge range of Aircraft from 1943 onwards with the most numerous being the use of the O-200 in the Cessna 150. Form X-30010, FAA Approved in April 1973. Manual published by Teledyne Continental Motors, Aircraft Products Division. Also included on the CD is an Adobe Acrobat version of the manual for easy browsing (Adobe Reader 7.0 supplied on the CD). Comes in a nicely printed Jewel case. See my other auctions for more vintage aircraft and engine manuals. Original Manual also available for purchase. Contact Seller for details.

Contents

SECTION I - INTRODUCTION

Model Designations

Definitions and Abbreviations

Measurement

Cleanliness

SECTION II – TABLE OF SPECIFICATIONS

SECTION III – GENERAL DESCRIPTION

Difference between Model Groups

Significance of C Series Dash Numbers & Letters

Model Conversions

Optional Equipment

Superseding Parts

Crankcase Construction

Crankshafts

Nitrided Crankshafts

Crankshaft Gears

Hydraulic Valve Lifters

Pushrods & Housings

Piston Assemblies

Cylinder Assemblies

Crankcase Cover Assembly for -12, -14, -16 & O-200 Models

Crankcase Cover Assembly for -8 Models

Gear Train

Carburetor Induction System

Oil Sumps

Ignition System

Delco-Remy Starter

Prestolite Starter

Generator & Drive

Side Mounted Fuel Pump

Dual Fuel Pump Equipment

Lubrication System

SECTION IV – UNPACKING THE ENGINE

Shipping Crates

Method of Packing & Preservation

Removal of Engine from Crate

Preparation for Installation

SECTION V – STORAGE OF ENGINES

Flyable Storage

Temporary Storage

SECTION VI – INSTALLATION IN AIRPLANE & REMOVAL

Mounting the Engine

Fuel System

Oil System

Propeller Installation

Engine Removal

SECTION VII – OPERATING INSTRUCTION

Procedure Preliminary to Starting

Starting Procedure

Warm-Up

Ground Test

Take-Off

Climbing

Level Flight

Let-Down & Landing

Stopping the Engine

Lubricating Oil

Engine Fuel

SECTION VIII – ENGINE TROUBLES AND SERVICE REPAIRS

SECTION IX – PERIODIC INSPECTION & MAINTENANCE

Daily Inspection

First Fifty Hour Inspection

100- Hour Periodic Inspection

SECTION X – ADJUSTMENT AND MINOR REPAIR

Carburetors

Magnetos

Replacement of Ignition Cables

Delco-Remy Starter

Prestolite Starter

Generator & Drive

Hydraulic Valve Lifters

SECTION XI – DISASSEMBLY

Preliminary Operations

Disassembly

SECTION XII – CLEANING

Materials & Processes

Specific Parts

SECTION XIII – INSPECTION

Definitions

Inspection Tools

Inspection Methods

Inspection of Critical Parts

SECTION XIV – REPAIR & REPLACEMENT

General Repair

Repair & Replacement of Specific Parts

Protective Coatings

SECTION XV – ASSEMBLY OF SUBASSEMBLIES

General Procedure

Detailed Procedure

SECTION XVI – FINAL ASSEMBLY

General Procedure

Detailed Procedure

SECTION XVII – TESTING AFTER OVERHAUL

Testing Equipment

Test Stand

Instruments

Test Club

Engine Test After Overhaul

Fuel & Lubricating Oil

Testing Engine Installed in Aircraft

Inspection

SECTION XVIII – TABLE OF LIMITS

LIST OF TABLES

Features Common to all Models

Type Certificate Numbers

Features Peculiar to Each Model Group

Dimensions Peculiar to Each Model or Model Dash Number

Speed and Power Ratings

Operating Temperature Limits

Operating Pressure Limits

Model or Model Dash Number Equipment

General Ignition System Specifications

Ignition Timing

Valve Mechanism Specifications

Lubrication System Specifications

Fuel Metering System Specifications

Accessory Drive Speed Ratios and Rotation

Line & Instrument Connections

Weights of Standard Engine Equipment

Additional Weights of Optional Equipment

Recommended Oil Viscosity Grades

Magnaflux Inspection Data

Stud Inspection Chart

Test Operating Limits

Test Schedule

Oil Sump Capacity

General Use Tightening Torques

Pipe Plugs

LIST OF ILLUSTRATIONS

Left Side View , Model C85-12F

Three-Quarter Right Rear View , Model C85-12

Three-Quarter Left Front View, Model C90-16F

Three-Quarter Right Rear View, Model C90-16F

Right Front View, Model C90

Left Front View, Model O-200

Cylinder Arrangement Diagram (Top View)

Section Through Hydraulic Valve Lifter

Crankcase Cover and Accessories of -12, -14, -16 and O-200 Models

Gear Train of -12, -14, -16 and O-200 Models

Hoisting Engine By Crankshaft Lifting Eye

Typical Installation Diagram for -12, -14 and -16 Models, Side View

Installation Drawing for -12, -14 and -16 Models, Front View

Installation Drawing for -12, -14 and -16 Models, Rear View

Installation Drawing for -12, -14 and -16 Models, Side & Top Views

Engine Mounting Equipment of Models C90-14 & 16 and O-200

Ignition Wiring Diagram

Removal of Hydraulic Unit from Valve Lifter Body

Compressing Valve Spring to Remove Locks

Removing Plunger from Hydraulic Unit with Taped Pliers

Installing Helical Coil Inserts

Dimensions of Rocker Shaft Boss Bushings

Tightening No. 1 Connecting Rod Bolts

Installing Crankshaft Bearing and Old Type Thrust Washer

Installing Crankshaft and Connecting Rods

Installing Dowel Type Thrust Washers and Split Oil Seal

Installing Starter Pinion Pivot

Installing Crankcase 1, 3 Side on 2, 4 Side

Installing Crankcase Cover on -12, -14, -16 and O-200 Models

Installing No.3 Cylinder

Installing “O” Rings on Intake Manifold Studs

Placing Crankshaft in Firing Position of No.1 Piston

Placing Flange Crankshaft in Firing Position of No.1 Piston

Fuel Flow Limits vs. R.P.M. at Propeller Load, Model C90

Fuel Flow Limits vs. R.P.M. at Propeller Load, Models C75 and C85

Fuel Flow Limits vs. R.P.M. at Propeller Load, Model O-200

Limits and Lubrication Chart (Sheet 1 of 4) – Cross Section View

Limits and Lubrication Chart (Sheet 2 of 4) – Longitudinal Section View

Limits and Lubrication Chart (Sheet 3 of 4) – Rear View and Horizontal Section -8 Models

Limits and Lubrication Chart (Sheet 4 of 4) – Rear View and Sections, -12, -14 and O-200 Models

** Note that the sample pages are a much lower resolution than those on the CD.

Please contact with further enquiries.

CD sent via First Class Airmail from Australia

Delivery within 10 working days of payment

Payment via PAYPAL to buyers outside Australia.

Australian buyers: payment by most methods

|

Continental aero engines c75 c85 c90 & o-200 parts list illustrated on cd

Continental aero engines c75 c85 c90 & o-200 parts list illustrated on cd Continental aircraft engines a50,a65,a75,a80 manual cd

Continental aircraft engines a50,a65,a75,a80 manual cd Pilot handbook owning operating your own aircraft rod simpson 2002 aviation book(US $16.89)

Pilot handbook owning operating your own aircraft rod simpson 2002 aviation book(US $16.89) Beechcraft manual model h35 and after parts catalog

Beechcraft manual model h35 and after parts catalog Beechcraft manual model v35b and after parts catalog

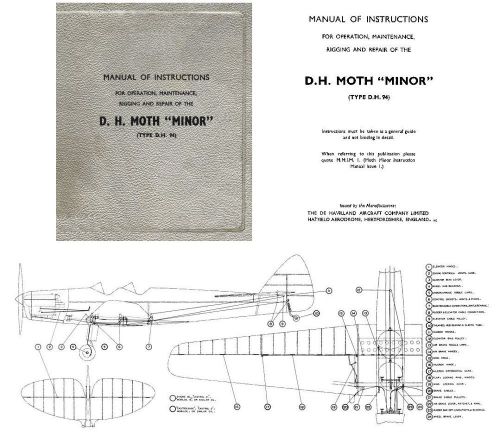

Beechcraft manual model v35b and after parts catalog D.h. 94 moth minor manual of instructions on cd

D.h. 94 moth minor manual of instructions on cd