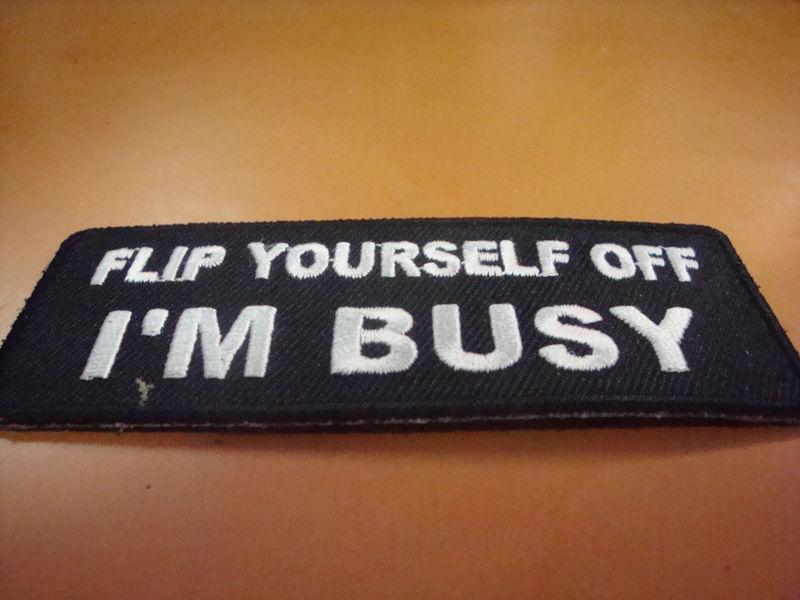

Flip Yourself Off I'm Busy Biker Patch New!! on 2040-parts.com

Pecos, New Mexico, US

"Flip Yourself Off I'm Busy" Biker Patch

NEW!

Embroidered

Approx. 4" wide and 1 1/2" High

Sew on, Iron on or Glue on

Great Patch!

Thanks for looking!!

Posted with eBay Mobile

Patches for Sale

Flying superman patch new!!(US $5.49)

Flying superman patch new!!(US $5.49) Woody racing flag biker patch new!!(US $4.99)

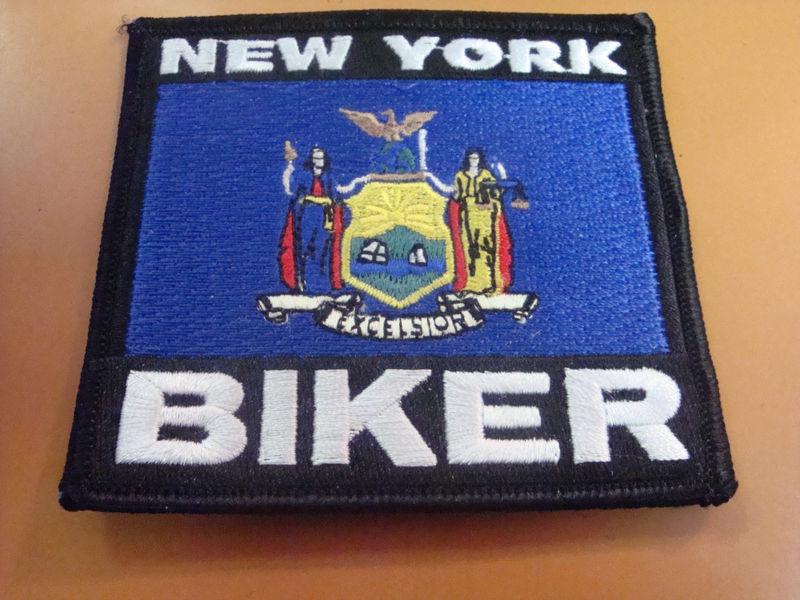

Woody racing flag biker patch new!!(US $4.99) New york biker patch new!!(US $5.49)

New york biker patch new!!(US $5.49) Danger contents under pressure biker patch new!!(US $4.99)

Danger contents under pressure biker patch new!!(US $4.99) Skulls with maltese cross biker patch new!!(US $3.99)

Skulls with maltese cross biker patch new!!(US $3.99) Beer = smiley biker patch new!!(US $3.59)

Beer = smiley biker patch new!!(US $3.59)

Concept Car of the Week: Renault Racoon (1992)

Fri, 16 Aug 2013As far as wacky concepts go, the Racoon surely has to be up there with the best of them. Designed and engineered like no other car before, the off-road and amphibious capabilities of the Racoon stretched automobile versatility to new levels. With its big eyes and smiley face, it has the same happy expression as its sister, the Twingo.

Mercedes R-class facelift (2010) first official pictures

Wed, 31 Mar 2010This is the facelifted Mercedes R-class, unveiled today at the 2010 New York auto show. It lives, and in the UK the new model will only be available as an entry level, rear-drive R300 CDI and a top-spec, long-wheelbase R350 CDI. The R300 CDI BlueEFFICIENCY 2WD (to give this big beast its full name) is 7% more efficient than before but still offers the same power and performance. The more snappily titled R350 CDI 4MATIC is also more economical (its 33.2mpg bettering its predecessor by 2.8mpg) but also more powerful, with outputs of 261bhp and 457ft up from 218bhp and 376lb ft.

Ford invents agile, low-cost solution for prototyping, customization and limited production [w/video]

Wed, 03 Jul 2013A new metal forming technique pioneered by Ford that drastically reduces the time and cost of producing low-volume and one-off body parts may lead to cost-effective customization, redesigns, one-offs and limited production runs. Ford Freeform Fabrication Technology (F3T) forms sheets of metal by two stylus-like tools, one on each side of the surface. Using CAD data they form the part to the exacting strength and finish tolerances usually associated with stamping dies.