|

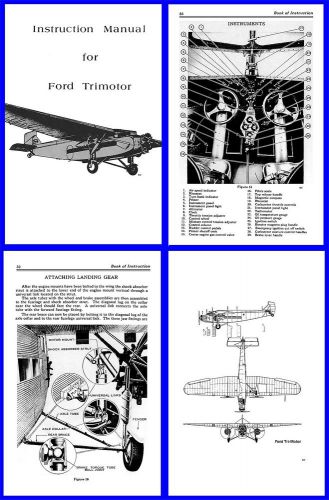

Book of Instruction – Ford All-Metal Monoplane .

Perfect scanned copy. 113 pages scanned as High resolution TIF images and then digitally cleaned page by page. This manual covers the Operation, Erection, Maintenance & Service of the Ford Trimotor and is packed with invaluable data including many detailed illustrations and Photographs ( See detailed Contents List below). Manual printed in 1929 by the Ford Motor Company, Dearborn Michigan. Also included on the CD is an PDF version of the manual for easy browsing (Adobe Reader 7.0 supplied on the CD). Comes in a nicely printed Jewel case. See my other auctions for more vintage aircraft and engine manuals.

Contents:

Introduction

Contents

PART I – GENERAL INFORMATION

Suggestions on the Operation of The Ford Trimotor

Must Know Air Traffic Rules

Do Not Overload Plane

Taking off

Two Engine Performance

Directional Control

Do Not use Brake Unnecessarily

Engine Instruction Book Should be Studied Carefully

Use Oil and Gasoline of Correct Specification

Gasoline & Oil Lines

Carburetor Operating Temperatures

“V” Type Windshield

General Description of The Ford All-Metal Monoplane

Fuselage

Cabin Interior Equipment

Pilots Compartment

Wing

Ailerons

Control Surfaces

Landing Gear

Brakes

Tires

Tail Wheel

Instrument Equipment

Power Plant

Fuel System

Specifications

General Dimensions

Performance

Weights - Loads - Tank Capacities, Etc

Cabin Data

Power

Equipment

Standard Equipment – All Models

Brakes

Storage Battery

Instruments

Toilet Compartment & Equipment

Miscellaneous

Special Equipment (Installed only on Request)

PART II – SHIPMENT OF AIRCRAFT

Erection Procedure

Installing Outboard Engine Assemblies

Attaching Landing Gear

Attaching Wing Tip Sections

Mounting Tail Surfaces

Connecting Surface Controls

Mounting Tail Wheel

Instructions for Starting

Starting

Running In New Engines

PART III – SERVICE INSTRUCTIONS

The Fuselage

Cabin

Floor

Windows

Doors

Wing Center Section

Fuel Tanks

Wing Hold Down Bolts

Wing Drag Bracing

Baggage Compartment

Fittings

Ailerons

Tail Surfaces

Stabilizer Brace

Fin

Rudder

Elevator

Axle Tube Assembly

Terminal Joints

Shock Absorber Units

Wheel Assembly

Removal of Wheel

Wheel Inspection

Bearing Adjustment

Toe-in & Camber

Removing Tires

Mounting Tires

Brake Tension Tube

Fender Assembly

Hydraulic Brake System

How The Brakes Operate

Description Of Brakes

Brake Shoe Adjustment

Removal of Brake Shoes

Wheel Pistons

Hydraulic Lines

Master Cylinder

Connecting Hydraulic Brake Assembly

Servicing Brake System

Cautions Regarding Ford Servo-Hydraulic Brakes

Surface Controls

Control Column

Aileron Adjustment

Elevator Cables

Rudder Control

Removing Rudder pedals

Stabilizer Adjustment

Stabilizer Indicator

Stabilizer Adjustment Screw

Tail Wheel

Engine Controls

Engine Cowling

Fire Extinguishers

Repairing Skin

Aluminum Alloy

Heat Treatment of Aluminum Alloy

PART IV – FUEL SYSTEM

Fuel System

Refueling

Gasoline Gauges

Description

Operation

Troubles & Repairs

Replacing Units

The Oiling System

Oil Pipes Lagged

PART V – ELECTRICAL SYSTEM

Electrical System

Adding Water to Battery

Care to be given to Plugs & Connections

Gravity Readings

Charging the Battery

Lighting Equipment

Running Lights

Cabin Lights

Instrument Lights

Landing Lights

Focusing Landing Lights

Alignment

Bulbs Used

Ignition Switches

Ignition Wires

Starter System

The Booster Magneto

The Generator

PART VI – INSTRUMENTS – NAVIGATION AND ENGINE

Instruments

Air Speed Indicator

The Pitot-Static Tube

Possible Causes of Trouble

Turn Indicator

Tachometer

Altimeter

Climb Indicator

Construction & Operation

Magnetic Compass

Parachute Flare

Oil Pressure & Oil Temperature Gauges

Clock

PART VII – PROPELLERS

Propellers

Assembling Propeller to Engine

Special Bolts for Clamping Rings

Straightening of Propeller Blades

Static Balance of The Propeller

Static Balance with the Blades in the Vertical Position

Dynamic Balance of the Propeller

Care of propeller Blades

Method of Inspecting propellers

PART VIII – INSPECTION OF PLANE

Inspection

Washing the Plane

Daily Inspection & Service Record

General Inspection & Service Record

Flight & Mechanical Report

Airplane Inspection Report

Special Bolts

Recommended Service Tools for Repair Depots

Equipment for Repair Depots

INDEX

** Note that the sample pages are a much lower resolution than those on the CD.

Please contact with further enquiries.

CD sent via First Class Airmail from Australia

Delivery within 10 working days of payment

Payment via PAYPAL to buyers outside Australia.

Australian buyers: payment by most methods

|

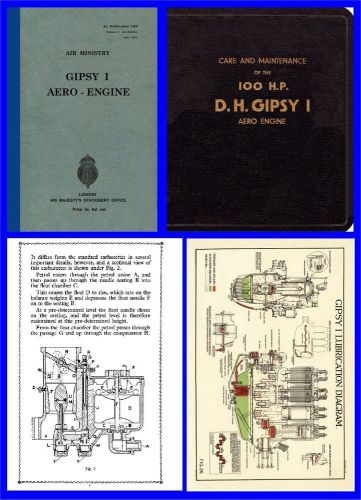

Gipsy i aero engine manuals x 4 on cd - dh60 etc

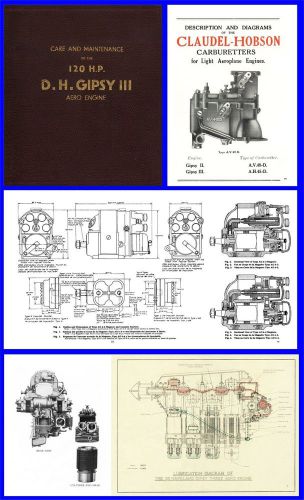

Gipsy i aero engine manuals x 4 on cd - dh60 etc Gipsy iii aero engine manuals x 4 on cd

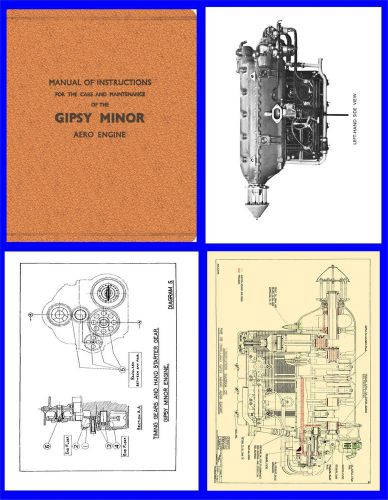

Gipsy iii aero engine manuals x 4 on cd Gipsy minor maint & overhaul manual on cd - moth minor

Gipsy minor maint & overhaul manual on cd - moth minor Gipsy six engine manual cd - dh88 comet, vega gull etc

Gipsy six engine manual cd - dh88 comet, vega gull etc Jaguar aero engine 1930's manual cd ap1139 & ap1346

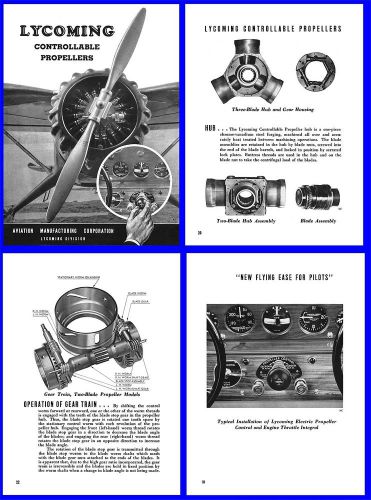

Jaguar aero engine 1930's manual cd ap1139 & ap1346 Lycoming controllable propellers 1937 booklet on cd

Lycoming controllable propellers 1937 booklet on cd