Honda B20/b18l/s Racing Custom Aluminum Connecting Rods on 2040-parts.com

West Palm Beach, Florida, US

CONNECTING RODS ARE ONLY FOR

RACING NO STREET USE .

THESE ARE "I" BEAM RODS WITH 21MM PISTON PIN

Specifications:

3/8 ARP Bolts

Torque Specs

50 FT/LBS

Connecting rods are produced in two major designs, the "I" Beam and the "H" Beam.

The "I" Beam design is used in almost all production engines. An "I" Beam rod can handle high compressive loads while also providing good tensile strength. The design of the "I" Beam allows for the rod to have better tensile strength and is the choice for high RPM engines.

An "H" Beam rod has two flat sides that are perpendicular to the piston pin, with a thin center section in the middle. The "H" Beam design is very stiff so it can handle higher compressive loads than an "I" Beam without bending. In high RPM operation the "H" Beam connecting rod should not be used, the design limits the amount of material that can be added and will lack the tensile strength required. Most "H" Beam rods are lighter and stronger than stock rods because they use less material combined with better engineering. "H" Beam rods are good for low level power production.

Connecting Rods can be made from various grades of steel, aluminum, and titanium. Steel rods are the most widely produced and used type of connecting rods. Their applications are best used for daily drivers and endurance racing due to their high strength and long fatigue life. The only problem with using steel rods is that the material is extremely heavy, which consumes more power and adds stress to the rotating assembly. Performance steel rods can be made from 4340 and even 300M grade steel. The tensile strength, yield strength, and hardness of 4340 steel depends on the temperature at which the steel is forged, and how the steel is heat treated. Variations in the tempering temperature and quenching procedure can produce extremely different results with tensile strength and yield strength. This is why it is important to buy your rods from a reputable manufacturer. 300M steel alloy is stronger than 4340 and can be used to manufacture steel rods that are lighter than their 4340 counter parts by using less material. 300M rods rated at the same strength level as 4340 rods can be 10% to 25% lighter.

Aluminum rods are used widely in high horsepower, high revving drag engines. Aluminum rods can be manufactured to the same strength level as a steel rod due to large amount of material that makes up the rod but still be 40% lighter than a steel connecting rod. Reducing the weight of the rods reduces the mass of the rotating and reciprocating parts and allows the engine to rev faster and rev higher safely. In addition to better throttle response than steel, aluminum’s lighter weight can reduce vibration and stress on the crankshaft. This reduced stress from inertia loading results in connecting rod journal bearings looking "good as new" after thousands of miles. The rods can stretch, and they may fatigue and fail, but unlike the aluminum rods from the 70's modern aluminum rods are much stronger and can be used in daily drive engines.

Titanium rods are both lighter and stronger than steel. Unfortunately titanium is extremely expensive so they are only used in drag racing and endurance racing applications in the most expensive engines. Unless you are building the ultimate in endurance racing engines use a steel rod. For drag racing, using an aluminum rod is both cheaper and lighter than using titanium.

For more Parts Click on the picture

Pistons, Rings, Rods & Parts for Sale

Wiseco pistons molnar rods acura honda b18 ls engine non-vtec(US $785.00)

Wiseco pistons molnar rods acura honda b18 ls engine non-vtec(US $785.00) Pressure plate bolt set honda b18.d16.k20/24 series-s2000 f20 -f22(US $19.99)

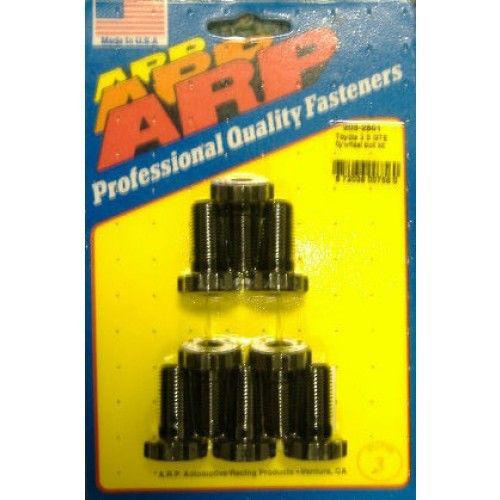

Pressure plate bolt set honda b18.d16.k20/24 series-s2000 f20 -f22(US $19.99) Toyota 3sgte flywheel bolts kit - arp 203-2801(US $44.99)

Toyota 3sgte flywheel bolts kit - arp 203-2801(US $44.99) Cp forged pistons mazda miata 323 1.8l 9.0:1 83.0mm(US $580.00)

Cp forged pistons mazda miata 323 1.8l 9.0:1 83.0mm(US $580.00) chevy mopar 327 350 351 360 trw piston rings t7556mx .060(US $9.99)

chevy mopar 327 350 351 360 trw piston rings t7556mx .060(US $9.99) Mishimoto performance aluminum radiator for subaru impreza wrx and sti (US $270.00)

Mishimoto performance aluminum radiator for subaru impreza wrx and sti (US $270.00)

Power Boost For Vauxhall’s Sporty Astra GTC

Tue, 07 Jan 2014VAUXHALL has boosted the performance of its three-door Astra GTC with the inclusion of a new 1.6-litre turbo petrol motor. Slotting in below the firm’s hot VXR variant, this latest addition to the Astra range boasts 197 horsepower and is the same unit that also powers Vauxhall’s premium drop-top, the Cascada. On-paper performance figures promise a brisk driving experience, with the 1.6 turbo Astra GTC topping out at 143mph and capable of sprinting to 60mph in 7.3 seconds.

BMW Concept 5-series ActiveHybrid (2010)

Sun, 28 Feb 2010By Tim Pollard First Official Pictures 28 February 2010 06:30 BMW's new 5-series will quickly spawn a petrol-electric hybrid – as this Geneva motor show 2010 concept car proves. It'll be the third BMW hybrid car in production, after the ActiveHybrid X6 and ActiveHybrid 7. Like the part-electrified 7-series, the Concept 5-series ActiveHybrid uses a straight six petrol engine with twin turbos and an eight-speed auto with a hybrid module built in.How clean is the new BMW Concept 5-series ActiveHybrid?Munich says both fuel consumption and CO2 emissions are improved by 10% and a zero-emissions EV mode is available, as the hybrid 5 is a full hybrid.

Audi A3 at 2012 Geneva motor show

Mon, 05 Mar 2012This is the new Audi A3, revealed on the eve of the 2012 Geneva motor show at the VW Group’s traditional pre-show party. This third-generation A3 is built on the VW Group's new MQB platform, is lighter than its predecessor, will eventually be sold in hybrid guises, and boasts high-end technology that even the Audi A8 limo doesn’t have. So what should I know about the new Audi A3?