Professional Tunable Ecu, Set Master 4tci, 1-4 (6-8 With Waste Spark) Cylinders on 2040-parts.com

Ostrava-Moravská Ostrava, default, CZ

ECU Master ignition - in general

The product MASTER ignition is a brand new series of ECU units without any direct succession to the previous models. It is the experience in development of industrial and transport safety systems, ignition units and particularly our customers’ needs which provided a foundation for the idea and realisation of the new model.

The unit MASTER ignition has been functionally designed in order to advance or injection control of ignition engines ranging from one to sixteen cylinders (depending on type), with whatever configuration of scanned teeth, types of sensors and features like 5D maps of advance and injection control, integrated pressure sensor, temperature, tachometer output, strobe lamp, charging control, engine speed and turbo preassure PID regulation, control switching on of fuel pump. MASTER unit contain CDI, TCI or combined outputs.

The list of features mentioned above determines MASTER ignition to be used either for a service or tunning replacement of all conventional motorcycle or automobile ECU units, usable for ignition or injection coil control. The integrated redundancy of sensing, together with other key features makes Master ignition very suitable for marine and aviation applications, moreover, thanks to the wide range of operating revolutions can be also used for turbines.

The function of MASTER ignition relies on FPGA technology, which provides digital-analog conversion of sensor signal, as well as its evaluation and calculation of the mathematical model of the real rotation. Simultaneously, it deals with other operations i.e. redundancy sensing, total control of CDI converter, advanced features and signal records. FPGA technology is interesting not only for its high operating performance but particularly for its accuracy, which in principle microprocessor-based systems cannot achieve.

Main Features

- The power supply range of 7 to 36 V (depending on type)

- Working speed from 0 to 120 000 rpm

- Operating temperature -40 to 85 °C

- Based on FPGA technology and microprocessor support

- Mathematical model of the real engine rotation, 64bit

- Adjustable pick up sensing levels, A/D conversion of signals, ± 25.5 V, 1Msps

- Angular maps of teeth, the voltage levels for different speeds, filters capture

- Customizing the input type sensor: Induction, Hall, Optical, Hammer

- Redundancy of sensing and other integrated elements

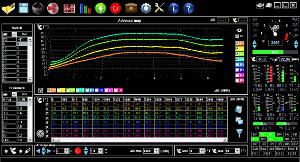

- Advance and Injection control – optional 5D map of ±360° and 0 to 60ms

- Integrated pressure sensor -80 to + 150kPa (depending on type)

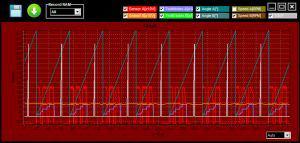

- Integrated oscilloscope, runtime visualisation of pick up and switching, ± 25.5 V, 1Msps

- Outputs – MOSFET and IGBT automotive – TCI, CDI or combined, 4 to 10 outputs

- Advanced functions – temperature, vacuum, vibration, tachometer, charge

- Integrated and configurable CDI converter 450V with superb performance of 100W

- User configuration by PC – while in operation with possibility of status visualization

- Galvanic isolated USB – common ground USB protection and EMC disturbation

- Measurement of voltage, temperature and load of converters

- Records – long-term and common, engine hours

- Convenient Firmware Upgrade – regulary and easy updates via the website

- Rapid diagnosis function using LED

Technical parameters

| Parameters | Range |

| Supply voltage | TCI … 7 – 36V CDI(12V) … 7 – 21V CDI(24V) … 12 – 36V |

| Current Consumption | TCI … < 100mA CDI … 0–10A, Dependent on the speed and voltage |

| Working speed (range management) | 0 – 120 000 rpm (0.1 – 65 000 rpm) |

| Working temperature | -40 – 85°C |

| Input mode (PA, PB) | ±25.5V, ±0.1V – ±50V, sampling 1Msps |

| Input mode (PA, PB) | ±25.5V, ±0.1V – ±50V, sampling 1Msps |

| Maps advance [1]…[8] | ±360°, 8 × 1024 pts, (0.1–65 000 rpm) |

| Maps injection [1]…[8] | 0–30ms, 8 × 1024 pts, (0.1–65 000 rpm) |

| Switching coil (1OA, 1OB, 1OC … 1OH) 2×, 4× or 8×, TCI, CDI (dependent on type) | TCI … MOSFET automotive 25A/300V CDI … IGBT automotive 16A/600V |

| Digital inputs (DI1–DI4) | 0 – 2V = L, 3 – 16V = H (Pull up 1kΩ) |

| Analog inputs (AI1–AI4) | AI1, AI2 … 0–5V; AI3, AI4 … 0–5V/0–10kΩ |

| Digital outputs (DO1, DO2) | MOSFET 5A/100V (Pull up 1kΩ) |

| Measurement of voltage (power supply) | 7 – 50V (tol. ±2%) |

| Temperature measurement (inside housing) | -40 – 125°C (tol. ±2°C) |

| CDI converter (voltage, pulse current, efficiency) | 100 – 450V, 2 – 24A, efficiency 62 – 75% |

| Resistance of primary winding coils* | CDI – Capacitance, resistance 0.1–1.5Ω TCI – Induction, resistance 0.2–25Ω (Pull up 1kΩ) TCI – Injection, resistance 0.2–25Ω (Pull up 1kΩ |

| Memory record | 8kB RAM, 8MB FLASH |

| Status indication by LED | Green, Red |

| User Configuration - USB | Freeware software MASTER control |

| Protection cover | IP65 |

| Package size | 105×95×37 mm |

| Weight | 350g |

* measured between terminals 1 (switching) and G (ground) for capacitive coil or 1 and 15 (supply) induction

Plugging

| Marking | Meaning | Range, Active Level |

|---|---|---|

| + | Voltage suply | 7 – 36V |

| G | Earthing power, sensors | 0V |

| 1OA-1OH | Switching coils A-H or user output | CDI – Capacitance, resistance 0.1 – 1.5Ω TCI* – Inductive, resistance 0.5 – 5.0Ω (Pull up 1kΩ) TCI* – Injection, resistance 0.5 – 5.0Ω (Pull up 1kΩ) |

| +PV | Power sensors output | +5V, 100mA |

| PA, PB | Rotation sensor A,B | ±25.5V, minimum 0.1V, sampling 1Msps |

| AI1–AI4/DI1–DI4 | Analog input AI1…4 Digital input DI1…4 | AI1,AI2: 0–5V; AI3,AI4: 0–5V/0–10kΩ DI1,DI2: 0–16V; DI3,DI4: 0–16V (Pull up 10kΩ) |

| DI1, DI2 | Digital input 1,2 | 0 – 1V = L, 3 – 36V = H |

| DO1, DO2 | Digital output 1,2 | MOSFET 5A/100V (Pull up 1kΩ) |

* TCI outputs it can be used for injection coils – switching, connection scheme is same as TCI

Other types of ECU MASTER

There are other unis available, but not at this offer and they are for different prices!!! If you are interested, send us a message and we will display your desired type:

Please note: TCI=outputs for induction coils or other use

CDI=outputs for capacitive coils

For more detail information please visit us at http://imfsoft.cz/hardware/products

Engine Services for Sale

Kia KH: First image of a new RWD Kia Flagship

Mon, 13 Feb 2012Kia takes aim at Lexus and Infiniti with the KH Concept Kia releases the first image of the Kia KH, a luxury RWD flagship saloon destined to be the Flagship for Kia and launching soon in Korea. It would have been unthinkable just a few years ago that Kia would reveal a new, luxury flagship saloon car and be taken seriously. But cars from South Korea have come a very long way, and plans for a range-topping luxury saloon from Kia are proof that they aim to take on the world’s premium car makers.

Gemballa MIG-U1 Enzo – details revealed

Tue, 12 Jan 2010The Enzo Ferrari based Gemballa MIG-U1 Just before Christmas a set of pictures of a Ferrari Enzo dropped in to our inbox. They turned out to be pictures of a modified Enzo created by Porsche specialist Gemballa and looked very appealing – although probably not to Ferrari aficionados who would no doubt think the Gemballa-ised Enzo to be sacrilege. But we didn’t have much detail on the Gemballa MIG-U1 (for that is the catchy little moniker Uwe Gemballa had attached to his Enzo creation) save what we could see.

Mercedes-Benz sells 1000,000 cars in a year in the UK for the first time

Sun, 01 Dec 2013Mercedes Bristol hands over the 100,000th Mercedes old in the UK in 2013 It looks like Mercedes move in to a more convincing compact car with the new A-Class is already paying dividends, with Mercedes announcing it has already broken the 100,000 car sales in the UK for this year with a full month still to go. The 100,000th car is, appropriately, a white Mercedes A 180 CDI Sport – perhaps the best-selling A-Class – which has been collected by its new owner from Mercedes-Benz of Bristol. This is the first full year the new A-Class has been on sale (although the first customer cars didn’t start arriving until well in to the new year) and augers well for sales numbers in 2014.

1 yr guarntee lexus acura toyota honda mercedes porsche ecm ecu repair rebuild

1 yr guarntee lexus acura toyota honda mercedes porsche ecm ecu repair rebuild 04 ford f250 350 diesel fuel injection control repair service 54 volt upg

04 ford f250 350 diesel fuel injection control repair service 54 volt upg