This unit was installed on a small Continental A-80 (same as an A-65 except the cylinders). From Rotec's web site, it fits small Continentals (such as the A-65 and O-200) and small Lycomings (Such as the O-235). From their web site:

The Rotec TBI-40 is the lightest, most compact and

simple Throttle Body Injector on the market today, its unique fuel

distribution system makes it a pleasure to set up and operate. With

excellent power per CFM and with the smoothest mixture control gained

via the leverage of a mechanical fuel injection bar.

Both the throttle body and remote fuel regulator are CNC machined from the highest grade aircraft Aluminium billet stock.

Fuel pressure and delivery are controlled via the Rotec "on

demand" fuel pressure regulator which is connected to the inlet side

of the throttle body and supplies the precise amount of fuel to the

injector bar. This system is truly self regulating and is not affected

by the fluctuation of fuel levels or pressures. One of engineering's

few "elegant solutions" .

The superior atomisation of the fuel is easily observed and

reflected in greater performance and economy. Regular carburetors do

not atomise the fuel nearly as fine or as well. Ultra fine atomisation

leads to the reduction of mixture temperature and as a result the

density of the incoming charge is greater and more power packed. Put

simply it burns better.

Also with the TBI-40's absence of any butterflies in the air

stream the total wetted area and drag is greatly reduced, resulting in

more throat area for the same size bore.

Another advantage of the slide throttle control is that unlike

the butterfly valve, the fuel mixture is not deflected into the side

walls of the inlet track where the mixture tends to accumulate and

loose the benefit of fuel atomising, The Rotec TBI-40 does not deflect

the mixture into the side wall and so the mixture remains freely and

completely atomised.

The Rotec TBI-40 is easy to set up and can run a wide range of

fuel pressure from 0.5 to 6.0 psi. It can even run in gravity fed mode

too. The TBI-40 is of course not attitude sensitive as it has no

float chamber so can run perfectly fine upside down!

Starting the engine from cold is simply a matter of depressing

the diaphragm over ride button on the Rotec fuel supply regulator,

this in effect gives the engine a squirt of fuel while cranking.

Typical primer nozzles can also be utilized if the airframe has

existing primer systems.

Idle speed is set via typical throttle aperture stop and bypass mixture screw which sets the idle fuel mixture.

Rotec Aerosport is offering the TBI-40 as an option over the regular Bing which is supplied as standard on the Rotec R2800 and R3600 radials.

Rotec R2800 and R3600 radials.

The Rotec TBI-40 is perfectly suitable for all Rotec radial

engines and will attach to the typical Bing rubber coupling. This

coupling makes the TBI-40 ideal for retrofitting many other engines

including the Jabiru engine range for which it will retrofit directly.

On request Rotec can supply a variety of custom engine couplings to

suite any Experimental engine including Lycoming and Continental

engines.

The slide throttle and mixture levers are controlled via typical

Bowden push pull cables. The air cleaner side of the TBI-40 is of the

standard aviation four bolt flange, designed to fit the standard range

of aviation air intake ducting.

Rotec advises that carburetor heat is a mandatory requirement.

FOR EXPERIMENTAL USE ONLY.

This unit is the 40-3, which is for Continentals and Lycomings. It was installed in 2013, and flew about 40 hours. Unfortunately, the aircraft it was on crashed due to fuel starvation, and was totaled. I bought the craft hoping to re-use the engine, but the crank was out of tolerance and I am/have parted it out. There are a few small marks on this TBI unit, either from a mechanic's wrench or from the crash. Please see detailed photos. The most significant issue (which I could easily hide, but will not ;-) is that the AN fitting on the fuel regulator snapped off. I had to remove the stub with an easy out, and there was light thread damage. I chased the trhreads with my 1/8 NPT tap. I have shown this slight defect in picture 3. In the other pictures, the AN fitting is threaded into the regulator at this location. This is the low pressure side of the regulator, where the fuel goes to the throttle body. Fuel is regulated at venturi pressure at this point. I would not hesitate to use this, and am only telling you about it by way of full disclosure. I would use teflon tape on the fitting, but I would do that anyway, as this is an NPT thread.

Rotec's web site is

www.rotectbi.com

.

This unit includes TBI manufactured on May 23rd, 2011, and the pressure regulator manufactured on the same date. I will guarantee this unit to be functional for 90 days after purchase. If it fails after being properly installed, I will issue a full refund if returned in like condition. I'll also take a return if you feel that the damaged thread compromises the fitting after you have seen it in person. (14 days for this reason, please.)

Rotec R2800 and R3600 radials.

Rotec R2800 and R3600 radials. 22ea screws bolt p/n bacb30nn3k3 titanium unsealed new.

22ea screws bolt p/n bacb30nn3k3 titanium unsealed new. Lycoming io-360 tachometer shaft assembly

Lycoming io-360 tachometer shaft assembly Lm2577s dc-dc adjustable step-up power supply module quantity 2

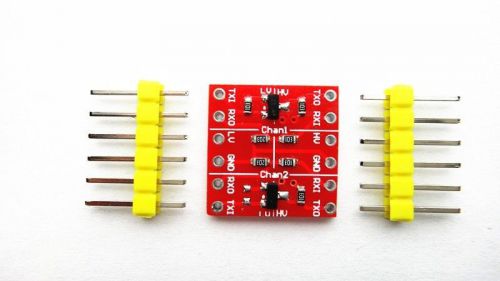

Lm2577s dc-dc adjustable step-up power supply module quantity 2 3.3v to 5v 2 channel logic level converter bi-directional module quantity 10

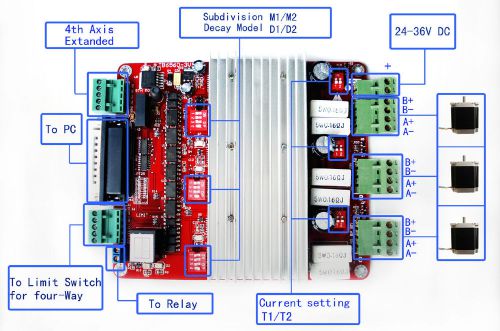

3.3v to 5v 2 channel logic level converter bi-directional module quantity 10 Cnc 3 axis tb6560 3.5a stepper motor driver controller board mach3

Cnc 3 axis tb6560 3.5a stepper motor driver controller board mach3 Hartzell aircraft alternator alx-8521r, 14 volt 70 amp

Hartzell aircraft alternator alx-8521r, 14 volt 70 amp