Sport Aircraft Plans Aircamper G-1 2 Place 24 X 36" 11 Prints Cruise 95mph on 2040-parts.com

Prescott Valley, Arizona, United States

|

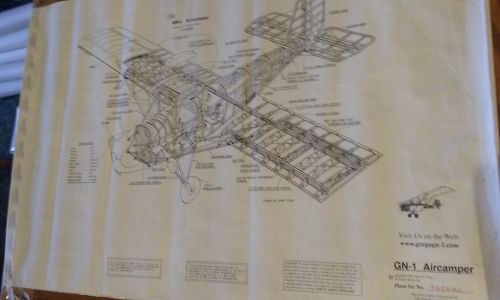

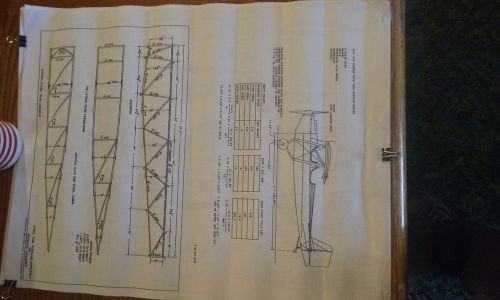

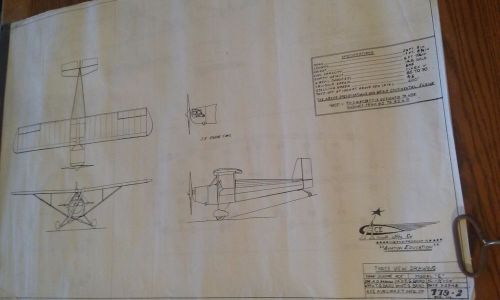

This auction is for a complete set of 11 prints for the GN-1 AIRCAMPER 2 PLACE AIRCRAFT. They are in like new condition and have never been used. These plans were produced by JOHN GREGA. The Grega GN-1 Aircamper was a light aircraft developed in the United States in the early 1960s, originally as a personal project of its designer, but later marketed in plans form for homebuilding. John W. Grega initially set out to create a modernised version of the Pietenpol AIR CAMPER using structural components from a Piper Cub but incorporating them into a new fuselage design based on the Pietenpol original. Two wings were designed, one based on the Cub wing, and another as a modernised version of the Pietenpol wing. Data from Air Trails General characteristics

Performance

For a GN-1 Aircamper having a gross weight (Wo) of 1100 lbs and a wing area (S) of 145 square feet, the wing loading (W/S) = 1100 / 145 = 7.59 lb per square foot (psf). I've decided on an engine for my GN-1 Aircamper. The engine I've selected is a TMX O-200 experimental engine manufactured by Teledyne Mattituck Services Inc.  Whilst it's not the cheapest option on the market I like the reduced risk offered by a proven powerplant constructed to a certified ISO 9001 quality system.  The TMX O-200 engine drives a fixed pitch propeller and delivers 100 HP. The engine weighs approximately 215 lbs. Overall dimensions are 23"x 31"x 28". Frequently Asked Questions

Disclaimer: I AM NO EXPERT!! ANY ANSWER IS JUST MY OPINION OR THE OPINION OF PERSONS I FORMED MY OPINION FROM. Chris

What is the difference between the Pietenpol Air Camper and the Grega GN-1 Aircamper? Basically the GN-1 is a modified Pietenpol that looks very similar to a Pietenpol when finished. However, anyone familiar with both designs can likely tell the difference. Pietenpol GN-1 I’m no expert on the GN-1 design because I am building a Pietenpol Air Camper, but I do have the plans for the GN-1 so I will try to list some of the differences.

There are more, but like I said, I’m not building a GN-1. One last thing …, note the difference in the name. A Pietenpol is called an Air Camper while the Grega GN-1 is an Aircamper. Note the Pietenpol is two words.

Aircraft grade spruce is expensive. What other wood can I use? Good question. People have used all kinds of wood to build airplanes, but the most common alternative wood is Douglas Fir (DF). DF is slightly heavier yet slightly stronger than spruce too. It is more prone to splintering, a bit harder to work using hand tools, yet cheaper and more abundant than spruce. Steve Eldredge in Utah built his nice green and silver Air Camper using, I believe, select DF flooring. Many other flying Air Campers have been built using DF. Others have had luck in ordering DF from Internet and local wood suppliers. Before you decide to use an alternative wood, make sure you get a copy of and know the grading standards. This way you can order the grade of wood you want or select it from the pile locally. You should know these standards even if you are using AC grade spruce as well (Not all AC graded wood is acceptable). You can find some good information in a book entitled "Acceptable Methods, Techniques and Practices" (AC43.13-1A). This book lists the properties of the most common alternative woods as they compare to spruce. Also, the EAA’s "Wood" book has a good article on grading wood, but this information can also be found in online sources. I remember one person saying he purchased 2"x12" DF boards because he could cut out spars from outer edges where the grain was more vertical. The best option, and if I would have known then what I know now, would be to use spruce for the 4 fuselage longerons, the complete tail group and the wing spars (If you can get some really good DF, I’d use DF for the spars too). All the other pieces I would make out of DF. You can also try to find Western Red Cedar. I hear it works great for the wing ribs and the turtle deck stringers. Don’t know if I would use it for spars.

I’m thinking about using Doug Fir for my Air Camper. If Doug Fir is stronger can I reduce the wood’s cross sectional dimension? Yes you could, but you need to know the engineering behind this to do it right. Also, once you go through all the calculations and effort, you are only going to save about 10 pounds. Personally, I think it would be easier to shave 10 pounds off the pilots’ weight than to try to save 10 pounds re-engineering the plane. Steve Eldredge’s Doug Fir Air Camper is lighter than some of the all spruce Air Campers, and as far as I know, he built his to the dimensions shown on the plans.

Aircraft grade plywood is expensive. What other wood can I use? I have heard of marine plywood, hoop pine, birch, and some stuff called "Aquatek" and "Hydratek" being used. Make sure you get a copy of the aircraft grade standards for plywood. Also check the British standards as some plywood is graded to this standard. Most important of all, use good wood with no voids between the plies.

I like the tall wire wheels. Where can I buy them? For information on building wheels, check out my Wire Wheel page. It sounds like it’s not that hard to do. Check out Mike Cuy’s and Larry Williams’ wheels to see just how nice a set of wheels you can build if you try. Ken Perkins makes and sells some really nice hubs if you don’t have the tools to build them yourself ($180 for the pair in 2006). Also, you can try Aerodrome Airplanes for some ready-made wheels, but I don’t know anything about their size or weight. I don’t want to use the Ford Model "A" engine. Can I use something else? Yes, it’s your plane. Use what ever engine you want. Ok, that’s probably too short of an answer. You can use any engine you want. However, some engines are too light in weight, such as the VW and Rotax engines. Remember that most Air Campers, without the Ford engine, turn out to be tail heavy (aft CG) when the wing support struts are installed vertically. If you replace the Ford a lighter weight engine, you are bound to be tail heavy unless you compensate for it (See question below). The most common alternative engines on an Air Camper are the small, A-65 to 0-200 size, aircraft engines (probably the only plane where you can call an aircraft engine an alternative engine). The Corvair engine is anotherpopular choice and one which Mr. Pietenpol designed. The Subaru engine as well as other auto conversions have been used successfully. Some even have a big old radial engine on the nose... man that looks good. (This is the engine I would use if I could afford one). By the way, you can purchase plans for the Corvair and Continental motor mounts from Andrew Pietenpol. Some people use solid 1" spars as shown on the plans. Others use laminated 1" spars (5 pieces if 1"x1" laminated together) and others use solid or laminated ¾" spars (Mr. Pietenpol did this on his last Air Camper). It’s up to your own personal preference on what to go with. Both seem to work fine. I’m opting for the 1" spar because I like the big beefy feeling to them. If you use the solid 1" spar do rout them. Yes, it makes a big mess, but it will lessen the weight. I’m not sure if you should rout a laminated 1" spar, but I don’t think you're supposed to rout the ¾" spars. What kind of steel should I use for the metal fittings? Well most people use 4130 steel. It costs more, but it is easier to find and is stronger. However, if you can find the 1020(25) steel, you can use that. The airplane was designed for this type of steel, so it should be strong enough. Where is the best place to buy (stuff)? First off, shipping will kill you. Buy as many parts as possible at one time. I shop at the local aircraft parts supplier for my bolts. I can stomach $10 every now and then instead of having to wait until I can order enough bolts to make the shipping cost acceptable. And Besides, I can buy the right size the first time instead of having to order two or three different lengths. 4130 Steel Get it from Dillsburg Aeroplane Works, 111 Sawmill Road , Dillsburg , PA 17019 . Telephone (717) 432-4589. I understand they have the largest selection of 4130 in the country. Rumor has it most, if not all, the homebuilt supply houses buy 4130 from them, so you might as well buy it from them directly without the added markup. They don’t have a web site or a catalog, just a price list. If you need something metal, call them they probably will have it. I hear they also sell hoses, rivets, fittings, turnbuckles and such. Also, try Aircraft Spruce and Wicks, but check on prices from each before ordering. Turnbuckles and other hardware B&B Supply in Gardner Kansas, 913-884-5930. Wood I haven’t found a good inexpensive source yet, so check prices at both Aircraft Spruce and Wicks. I have used wood from both. The long fuselage adds 2" in the first bay, 2" in the rear cockpit and adds 2-1/2" inches in the second to last bay and almost 3" in the last bay. Do I need Jurry Struts? The plans don’t show them, but you need them. Even Mr. Pietenpol said you need them. What are those struts which go from the wing to the engine mount?

Should I rout the wing spars? Yes, always take advantage to save weight. A lighter airplane will climb better. I want to make the wings fold. Many have thought this, but as of yet I have not seen anyone accomplish it. The closest is the British quick connect aileron fittings so the wings come off more easily. But I understand this is still a pain. If you come up with a good way I’d be interested in it too. The design looks kind of flimsy, so I think I will beef up the …….. No, don’t do it!!! It’s plenty strong and all you will do is add weight. But ultimately it’s up to you. If you really want to do it, first look at the Grega GN-1 plans to see if he already designed a beefed up component. It seems he did a lot of beefing up.

Can you recommend any books? Get the four books by Tony Bingelis:

EAA’s Wood book I also really like "Aircraft Maintenance for the Airplane Mechanic" by Daniel J. Brimm, Jr. and H. Edward Boggess, Pitman Publishing Corporation, New York-Chicago, 1940 (I got mine off the internet for $15). It is a good source for 1940 building techniques.

To braze or not to braze that IS the question. If you use the mild 1020(25) steel call out in the plans, brazing is fine. However, if you choose to substitute 4130 steel, you should weld. My understanding of this is when heated, the crystalline structure of 4130 opens up and allows the melted braze rod into the structure. Upon cooling the brazing metal contracts differently and causes, cracking of the 4130 steel and I think we can all agree this not a good thing.

|

|||||||||||||||

Plans for Sale

Sport aircraft plans aircamper corvair, cont. supplement update 15 prints(US $59.00)

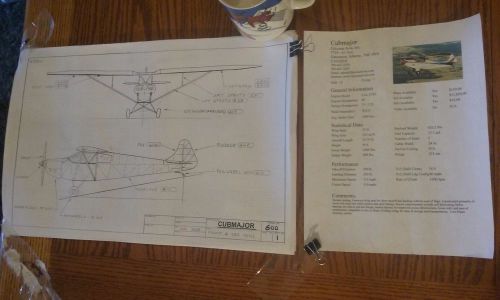

Sport aircraft plans aircamper corvair, cont. supplement update 15 prints(US $59.00) Stolaircraft plans cubmajor/ majorette 45 prints cr 110mph 330 ft takeoff 2 seat(US $150.00)

Stolaircraft plans cubmajor/ majorette 45 prints cr 110mph 330 ft takeoff 2 seat(US $150.00) Cri cri aircraft plans original

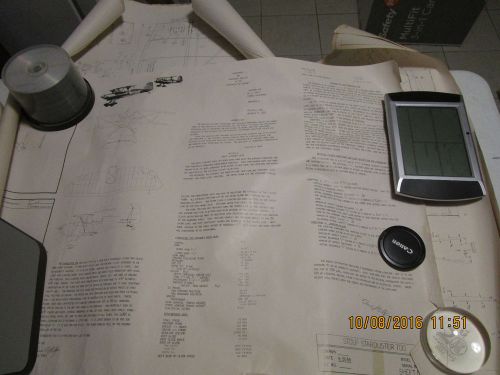

Cri cri aircraft plans original Starduster too aircraft plans

Starduster too aircraft plans Sport aircraft plans junior ace model e 2 place 24 x 36" 22 prints cr 95mph(US $150.00)

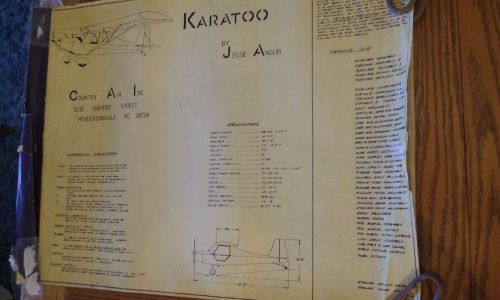

Sport aircraft plans junior ace model e 2 place 24 x 36" 22 prints cr 95mph(US $150.00) Sport aircraft (32)plans karatoo j-6 ultra light & lsa 24x18" cr 85mph cost $400(US $149.00)

Sport aircraft (32)plans karatoo j-6 ultra light & lsa 24x18" cr 85mph cost $400(US $149.00)

Is the 2013 Aston Martin Rapide getting more power and a facelift?

Fri, 03 Aug 2012The rumours are growing that Aston Martin are giving the Rapide a makeover for 2013 with more power and cosmetic tweaks. The rumours have been bubbling around for a while that Aston Martin are planning a more powerful Rapide for 2013, perhaps the Rapide S. But that rumour seems to be only partly true, as it looks like the Rapide is going to get more power – and a bit of a cosmetic tweak – but as a facelift and upgrade for the existing Rapide rather than a new Rapide S.

BMW launches new 5-series (2009 teaser

Tue, 10 Nov 2009It's begun - BMW has started the PR roll-out for the new 5-series. First up there's both a teaser video and a single image of the Five, before the new car is unveiled on 23 November 2009. There's one solitary image, and the video is typically brief, but BMW claims it's enough to give us a glimpse of 'the sporting and elegant design of the new BMW 5-series, using the kinetic sculpture from the BMW Museum to create the silhouette'.

Chat live with AutoWeek executive editor Roger Hart on Friday

Tue, 15 Mar 2011AutoWeek executive editor Roger Hart will field your questions at 12:30 p.m. on Friday. Roger just got back from the Amelia Island Concours d'Elegance, and he is editor of the CarLife section of the magazine.