Cleveland, OH: Oil is the life blood of the drive train. Without a constant, adequate supply, parts are destined for failure, sometimes at the most inopportune moment.

To accommodate, Weldon’s 9200-A oil transfer pump circulates hot oil in transmissions and differentials and has been designed to meet the demanding rigors of racing and OEM applications. They have been manufactured using the same stringent quality requirements and exacting specifications as Weldon’s electric racing fuel pumps.

Flow rate for the 9200-A is 30 gallons per hour of 300-degree F 80-90W differential gear oil or ATF. Further, the current draw is only 5.5 amps. At 3 pounds and measuring 2.50×5.40-inches, weight and dimensions are compact.

Why contemplate the 9200-A pump? Although very few are willing to divulge the information, the 9200-A is presently being used on a number of front runners’ superspeedway cars in Cup and Nationwide series. In fact, it is the only pump known to be used in circle track racing for transmission and differential cooling.

Further, it has been approved for use in export C5 and C6 Corvettes destined for warmer climates. Weldon is also working on a prototype high-temperature oil transfer pump for the new Cadillac CTS-V. This pump can be found in the GM Motorsports catalog under PN 12480080.

Features

Internal Relief Valve prevents system damage. The valve is designed to lift sufficiently to relieve fluid pressure build-up over setting. These valves help protect vessel and piping system damage from over pressurization. To ensure that oil pressure does not exceed the rated maximum, a spring-loaded pressure relief valve routes oil back to its source once pressure exceeds a preset limit.

Internal Relief Valve prevents system damage. The valve is designed to lift sufficiently to relieve fluid pressure build-up over setting. These valves help protect vessel and piping system damage from over pressurization. To ensure that oil pressure does not exceed the rated maximum, a spring-loaded pressure relief valve routes oil back to its source once pressure exceeds a preset limit.- Pumps are 100 percent serviceable/repairable

- Internal components are 100 percent metallic—no plastics or composite materials are used

- Compatible with all types of hot oils

- Resistant to contamination

- Blades self-compensating for wear

International Buyers - Please Note:

Internal Relief Valve prevents system damage. The valve is designed to lift sufficiently to relieve fluid pressure build-up over setting. These valves help protect vessel and piping system damage from over pressurization. To ensure that oil pressure does not exceed the rated maximum, a spring-loaded pressure relief valve routes oil back to its source once pressure exceeds a preset limit.

Internal Relief Valve prevents system damage. The valve is designed to lift sufficiently to relieve fluid pressure build-up over setting. These valves help protect vessel and piping system damage from over pressurization. To ensure that oil pressure does not exceed the rated maximum, a spring-loaded pressure relief valve routes oil back to its source once pressure exceeds a preset limit.

Tall deck chevy blocks 592, and 598

Tall deck chevy blocks 592, and 598 Racing power company r4870 chrome push-in breather cap imca nhra dirt drag

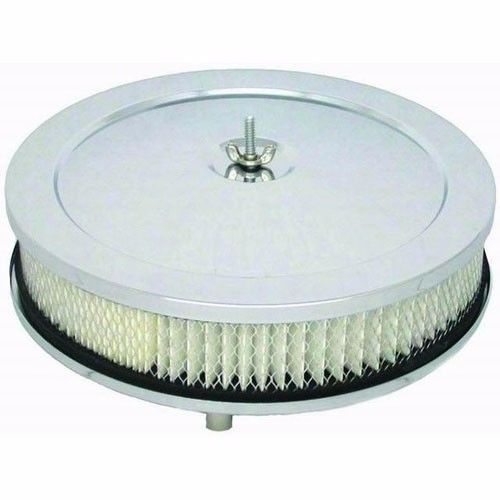

Racing power company r4870 chrome push-in breather cap imca nhra dirt drag Racing power company r2282 10" x 2" air cleaner kit imca nhra dirt drag

Racing power company r2282 10" x 2" air cleaner kit imca nhra dirt drag Outerwear 10-1014-01 14"x 4" with top black air filter pre filter imca dirt

Outerwear 10-1014-01 14"x 4" with top black air filter pre filter imca dirt Winters 67556 rear shaft bearing imca dirt circle track racing

Winters 67556 rear shaft bearing imca dirt circle track racing Allstar performance 72099 universal 9" ford axle housing seal imca circle track

Allstar performance 72099 universal 9" ford axle housing seal imca circle track