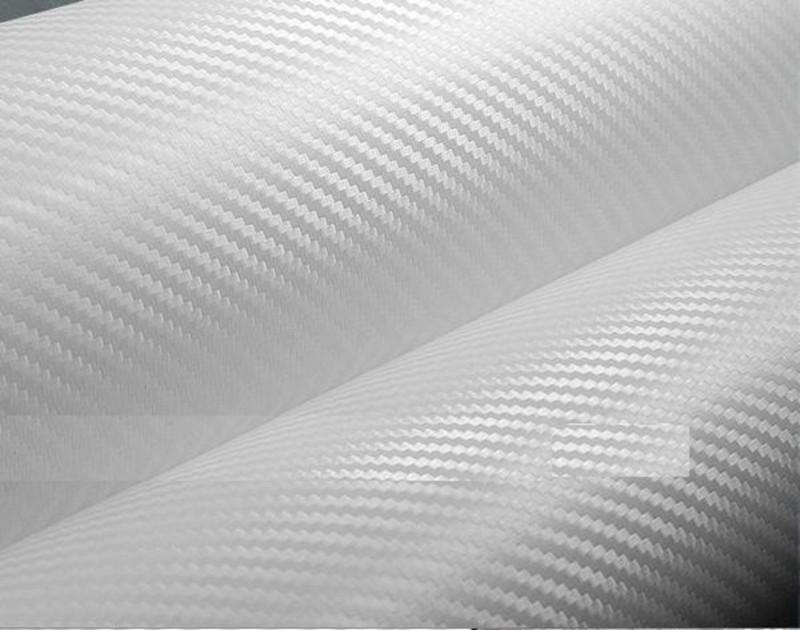

White 3-d Twill-weave Carbon Fiber Vinyl 24"x 60" Roll Wrap Sheets 2ftx5ft on 2040-parts.com

Elmont, New York, US

3D TWILL

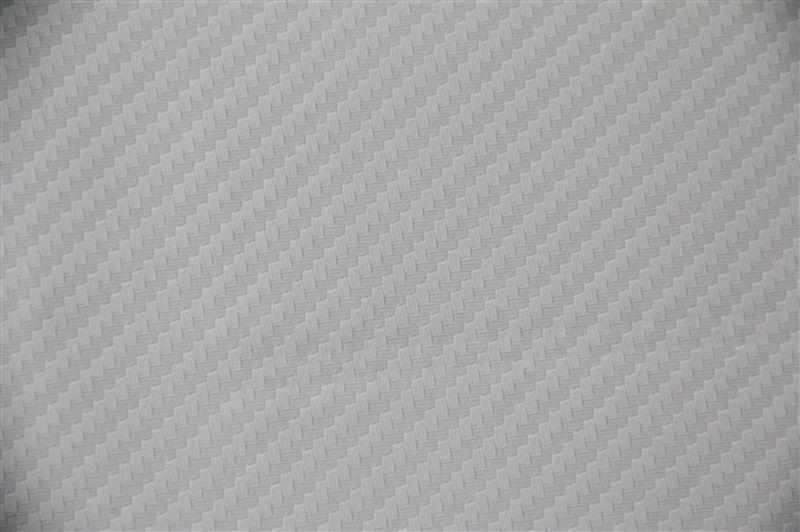

PICTURES ARE FOR ILLUSTRATION ONLY

THIS IS A BRAND NEW NEVER USED 24 INCH (2FT) X 60 INCH (5FT) ROLL OF THE BEST CARBON FIBER AVAILABLE

WHITE CARBON FIBER 24 IN X 60 IN

THIS VIEW IS THE BACK OF THE ITEM YOU WILL BE RECEIVING MAKING CUTTING AND MEASURING THAT MUCH EASIER

|

SHIPPING

WE SHIP MONDAY THRU FRIDAY 7AM TO 4PM EASTERN STANDARD TIME

1.Selecting Material

As with any product, the finished product is only as good as what you put into it. This begins with choosing the right vinyl for the job. Cast film is very thin (approximately 2 mil) and has excellent durability and conformability characteristics. The thin gauge of the film gives the product the "paint like" finish that many customers are looking for. When properly applied these films generally last 5 years. This makes cast film the ideal film for full vehicle wraps.

There are economy vehicle wrap options available from various vinyl manufacturers. Keep in mind that these economy vehicle wrap films are generally calendered films and will not have the same performance characteristics as cast films. For example, you can expect some degree of tenting (material lifting) in areas of the vehicle such as deep crevasses. These economy films are developed to provide a good looking graphics that will last up to one year at an economical price.

2. Before You Apply

The first step to applying any graphic is to clean your substrate. To ensure that the graphics adhere properly, without the risk of failure, we must thoroughly clean the vehicle. Proper cleaning of the surfaces of a vehicle for graphics application is a critical step in the application process.

Cleaning is to remove all of the dirt and grime with a commercial detergent and water. As you can see in this "before" photo, the vehicle was covered with dirt and salt because of the winter weather. Note: If you take the vehicle to the car wash, it is important to make sure the vehicle is completely dry before applying the graphics. This may mean allowing the vehicle to dry indoors overnight before applying.

If grease, oil, wax or other contaminants are present, wipe the substrate with a solvent such as Prep-Sol or Xylol. You can do a final cleaning with isopropyl alcohol (IPA) to make sure that no oily residue from the other solvents is left behind. CAUTION: Before using any solvent on a vehicle, be sure to test in an inconspicuous area to ensure the solvent won't damage the vehicle's paint.

When cleaning the vehicle with IPA, I recommend using two lint free towels. One towel should be soaked with IPA which is used to loosen and clean off the contaminants (dust, dirt, wax, etc.). The second towel should be dry and used to wipe away the excess IPA before it has a chance to evaporate. It is also important to pay special attention to cleaning the cracks and crevices of the vehicle where contaminants generally build up. For these areas, I recommend wrapping an IPA soaked towel around a squeegee to get down into the crevasses as shown here.

3.Tools of the Trade

Temperature plays an important roll in how well a vinyl sticks to a substrate. Vinyl manufacturers generally recommend the temps be in the range of 50-90F with 70-80F being the optimum range. Whenever possible, try to apply graphics indoors in a controlled environment. Not only will this help you control the temperature, it will also reduce the amount of wind, dust and other contaminants you have to deal with. It is important to monitor both the ambient and surface temperature as both can have an affect on your application. Higher temperatures will make the film soft and more pliable (which can be nice if you are an experienced installer). However, the high temperature also makes the adhesive more aggressive which can lead to pre-tack (this is where the film adheres to the substrate prematurely) and increased stretching if you try to reposition the film. Lower temperatures, on the other hand, will make the film more rigid and reduce the tack of the adhesive.

There are a few basic tools you will need to apply graphics. They are:

a tape measure - for positioning

an air release tool - for removing air bubbles

masking tape - for positioning

a squeegee - for applying the graphic

a razor-knife (preferably one with break-off blades) - for trimming away excess vinyl

a heat g un or propane torch - for heating the vinyl on complicated applications

It is now time to apply the graphic. This is where applying a full wrap greatly differs from applying cut vinyl graphics. Unless you are in a climate in the upper end of the recommended temperature range this construction has enough integrity to apply without stretching. If a pre-mask is used you will find yourself frequently removing strips of pre-mask as you need to conform around the vehicle contours.

It is possible to apply these large graphics alone (it is done all the time by experienced pros), however it is much easier if you have a second set of hands to help with positioning the film during the application process.

Start out by positioning the graphic and taping it into place. Since the hood isn't perfectly flat we can't follow the standard process of starting at the top and working our way down. In this case it will be easiest for us to start near the center and work our way up then go back and work down. Keep the squeegee at a lower angle helps avoid wrinkles.

The next piece we will apply is the side panel. Here we opted to do one long horizontal panel, which helps us eliminate seams in our graphic. This is possible on this particular vehicle because the 60" material is taller than the vehicle itself. This is also possible since we are applying indoors in a controlled environment. You may not want to use this method on hot day because we are removing all of the liner and will need to continually reposition the material during the application process. If the temperature is too high we are at risk of pre-tack and stretching the film.

When you reach the wheel well area, you can trim out the excess material this helps to relieve

As we near the front and rear bumpers it is necessary to take additional time and work the film to avoid wrinkles. In this second picture you can see that some wrinkles beginning to appear. It will be necessary to use heat to relax the film and continue to work the film into the contour of the vehicle. Remember the trick here is to take your time and not overheat or over-stretch the film.

The final step in the vehicle application process is to go back and trim the material around the moldings and door panels. Even though the film looks good in these areas at the time of installation, it is possible that some excessive stretching may have occurred and trimming the vinyl in these areas will prevent any tenting. It is also a good idea to go back and look for any air bubbles you may have missed while squeegeeing the material into place. Since this material has the easy-apply feature an air release tool is not necessary. Simply use your thumb or squeegee to remove the air bubble.

Graphics Decals for Sale

Vinyl sticker car vdv russian paratrooper decal film oracal(US $3.79)

Vinyl sticker car vdv russian paratrooper decal film oracal(US $3.79) Decals sticker sign signs warning danger caution stay away atv 0500 z3669(US $1.83)

Decals sticker sign signs warning danger caution stay away atv 0500 z3669(US $1.83) She wants the d duramax vinyl decal sticker chevy diesel truck 4x4 denali stacks(US $7.99)

She wants the d duramax vinyl decal sticker chevy diesel truck 4x4 denali stacks(US $7.99) Pontiac arrowhead big 13x23 red ***wow***pair(US $32.00)

Pontiac arrowhead big 13x23 red ***wow***pair(US $32.00) Pontiac firebird formula 4 caliper decals / gloss black(US $11.00)

Pontiac firebird formula 4 caliper decals / gloss black(US $11.00) Sg_st106 sticker decal motorcycle car bike racing tattoo moto motocross logo(US $1.79)

Sg_st106 sticker decal motorcycle car bike racing tattoo moto motocross logo(US $1.79)

Mercedes CLS63 AMG (2011/2012) LA Debut

Wed, 17 Nov 2010The Mercedes CLS63 AMG 2011 gets debuted at LA The Mercedes CLS is probably our favourite Mercedes. It’s the Black Sheep of the family that dares to eschew the family style and sensibility. It ploughs its own furrow beyond just the obvious four-door swoopy-coupe thing.

Make like a tree and Leaf: We drive Nissan's coming electric vehicle

Mon, 16 Nov 2009From behind the wheel, the production version of the Nissan Leaf electric car is smooth and silent, feels nearly friction-free and offers all the prodigious torque inherent in an electric car. That's what we found after a short drive around Dodger Stadium in Los Angeles on Friday. The body you see in the photo is a Versa.

Toyota FT-86 II: The second coming of the Toyobaru FT-86

Wed, 26 Jan 2011Toyota FT-86 II Tease Just last week we finally got the first concrete news on the Subaru half of the Toyobura project that seems to have been bouncing around forever. Well, certainly since Toyota first rolled out the Toyota FT-86 Concept at the Tokyo Motor Show in 2009. Which made is believe that the whole Rear-Wheel Drive Sports Car Technology Concept designed to deliver an affordable, traditional-style rear-wheel drive sports car at a sensible price (when we first saw the Toyota FT-86 we were told around £17.5k ) was finally going to bear fruit.